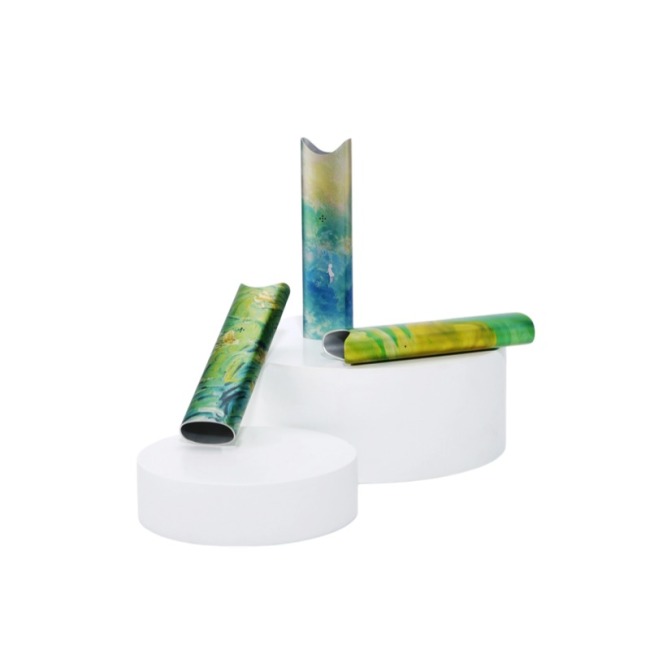

Electric Atomizer Enclosure-High-Gloss Polishing + Anodizing

Key Technical Advantages

| Feature | Benefit to Your Product |

| High-Gloss Polishing | Ultimate Aesthetic Value: Creates a true mirror finish that signifies luxury and demands a premium price point. |

| Transparent Anodizing | Brilliant Color Depth: Color is rich and vibrant due to high light reflection from the polished base. |

| Zero-Defect Process | Flawless Quality: Meticulous control of cleaning and sequencing guarantees a pristine final finish. |

| High Tolerance CNC | Seamless Assembly: Base component precision ensures perfect fit for critical atomizer components. |

- Item No. Coboggi-AC031MOQ 100 Piece

Choice

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

Precision Craftsmanship: The Ultimate Reflective Finish

This enclosure is the epitome of luxury and visual impact. It achieves a deep, mirror-like finish through meticulous High-Gloss Polishing—the most demanding surface preparation method—which maximizes the metal's reflectivity before the protective and colorful Anodizing layer is applied.

1. High-Gloss Polishing (The True Mirror Finish)

High-gloss polishing is a multi-stage process that systematically eliminates all microscopic imperfections and surface roughness, resulting in a flawless, mirror-like base:

Multi-Stage Mechanical Abrasion: The component first undergoes several rounds of mechanical buffing using progressively finer abrasive compounds. This stage removes the tooling marks and structural flaws left by the CNC process.

Chemical/Electrolytic Smoothing: To achieve the true optical mirror finish, the part is then often subjected to a precise chemical or electrolytic polishing bath. This process dissolves microscopic peaks and valleys on the surface, making it incredibly smooth and reflective.

Aesthetic Impact: The result is a surface with unparalleled reflectivity, where the aluminum acts like a true mirror. This finish is instantly associated with high-end, luxury consumer electronics.

Tolerance Demand: This process is extremely sensitive. Any imperfection in the CNC machining will be magnified exponentially by the high-gloss polish, demanding the absolute highest precision in the initial fabrication steps.

2. Anodizing for Depth and Protection

The Anodizing step is crucial to protect the fragile polished surface and introduce durable color:

Transparency is Key: We utilize a high-quality Type II Anodizing process that is carefully controlled to ensure the resulting oxide layer is as thin and transparent as possible. This is essential to prevent clouding the highly reflective surface underneath.

Color Brilliance: The mirror-like base reflects light back through the transparent, colored oxide layer, giving the final color an extraordinary sense of depth, brilliance, and vibrancy unmatched by matte finishes.

Protection for the Finish: Since polishing leaves the aluminum highly susceptible to scratching and oxidation, the dense, hard oxide layer created by anodizing seals and protects the high-gloss base, maintaining the aesthetic integrity of the mirror finish during use.

The coboggi.com Solution: Zero-Defect Polishing Management

At Aile Precision Hardware (coboggi.com), we specialize in delivering the most challenging surface finishes. Our OEM/ODM service is built to manage the exacting demands of High-Gloss Polishing and its integration with precision anodizing.

A. Mastering Complex Manufacturing (The "How")

We control the complete process chain to ensure every unit achieves the zero-defect mirror finish required:

"Polishing Ready" CNC: Our initial CNC machining protocols are adapted to produce parts that are "polishing ready," meaning they start with an exceptionally smooth surface finish to minimize the deep scratches that are difficult to remove in the subsequent stages.

Controlled Environment Finishing: Polishing is conducted in a clean, controlled environment to prevent microscopic dust and debris from being embedded in the surface, which would ruin the final mirror quality.

Strict Process Sequence: The sequence CNC -> Multi-Stage Polishing -> High-Purity Cleaning -> Anodizing is strictly governed. The cleaning step between polishing and anodizing must be absolutely flawless, as any residual polishing compound will cause defects (clouding or staining) in the final anodized layer.

B. Customization and Scalability (The "Why")

Flawless Visual Quality: We offer visual quality standards that meet or exceed those of the most demanding consumer electronics brands, guaranteeing a true, undistorted mirror finish.

Color Matching for Luxury: Our Bright Anodizing capabilities allow for rich, custom color development, providing a luxury finish that is consistently applied across the entire production run.

Scalable Output: Our specialized polishing equipment and automated chemical baths are optimized for high-throughput, ensuring we can scale production rapidly while maintaining the absolute highest level of surface quality on every single enclosure.

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish