In the Personal Care and Consumer Electronics categories, the logo is often the only thing that breaks a perfectly smooth surface.

If the logo peels or fades, the brand's perceived value drops instantly. Because we work with solid aluminum, we move beyond "printing" and into "marking" techniques that are as durable as the metal itself.

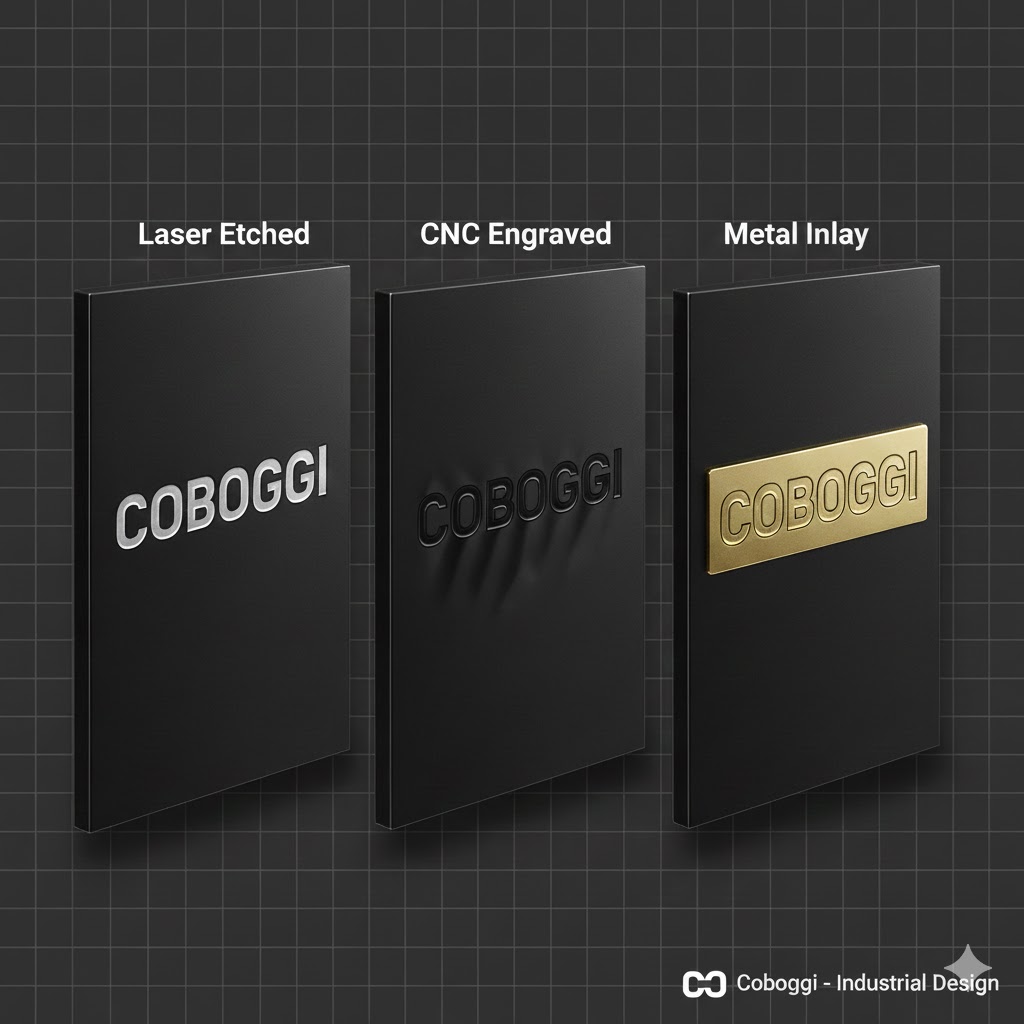

1. Laser Etching (Precision & Contrast)

This is the most common high-end solution, particularly for anodized parts.

The Process: A high-precision fiber laser "burns" off the microscopic top layer of the anodized dye, revealing the natural silver aluminum underneath.

The Result: You get incredible detail (high-fidelity enough for QR codes or complex regulatory symbols) with a crisp, clean contrast.

Best For: Personal Care items like trimmers where serial numbers and branding need to be sharp and permanent but flush with the surface.

2. CNC Engraving (Depth & Permanence)

When you want the user to feel the brand, you go deeper.

The Process: The logo is milled directly into the metal using a tiny ball-nose or V-shaped CNC bit before the part is anodized.

The Aesthetic: Light catches the edges of the engraving, creating shadows and highlights. It communicates that the logo was part of the product's birth, not an afterthought.

Best For: Home Goods like weighted bases or luxury remote controls where a "carved" look suggests heirloom quality.

3. Metal Inlays (The Ultimate Luxury)

For the highest tier of Electronics or Home Decor, we use mixed-material inlays.

The Execution: We CNC-mill a pocket in the aluminum and then press-fit or bond a separate piece of material—such as polished stainless steel, copper, or even wood—into the void.

The Impact: This creates a stunning material contrast (e.g., a "Gold" brass logo set into "Matte Black" aluminum) that is impossible to achieve through etching or engraving alone.

4. The Texture "Knockout" (Subtle Branding)

Sometimes, the most luxury statement is the quietest one.

The Strategy: We use a difference in texture to create the logo. For example, the entire body is Bead-Blasted (#68) to a matte finish, but the logo area is masked and Polished to a mirror shine.

The Effect: The logo only appears when the light hits it at the right angle. It’s a "secret" branding technique favored by minimalist high-end electronic brands.

Conclusion: Making Your Mark

A logo on an aluminum product should feel like it belongs there forever. Whether it’s the high-contrast precision of a laser, the tactile depth of an engraving, or the material prestige of an inlay, Coboggi ensures your brand mark is as resilient as the hardware it represents.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish