Every successful hardware startup reaches a crossroads.

Your prototype was a hit, the pre-orders are flooding in, and now you need to produce 100,000 units. Suddenly, the CNC machining process that worked so well for your first 500 units looks prohibitively expensive.

Should you stick with the precision of CNC or invest in the high-speed output of Die Casting? At Coboggi, we help brands navigate this transition every day. Here is the data-driven guide to making the right choice.

1. CNC Machining: The Precision Specialist

CNC (Computer Numerical Control) machining carves your enclosure out of a solid block of aluminum.

The Pros: No expensive molds (tooling) required. You can change the design on the fly. It offers the highest possible precision (±0.01mm) and the best surface finish.

The Cons: It is slow. Every second the drill is moving, it costs money. For 100,000 units, the cumulative labor and machine time are massive.

Best For: Prototyping, luxury low-volume products (under 5,000 units), or components requiring extreme structural integrity.

2. Die Casting: The High-Volume Hero

Die casting involves forcing molten aluminum into a steel mold (the "die") under high pressure.

The Pros: Once the mold is made, you can produce a part every 30–60 seconds. The cost per unit drops drastically compared to CNC.

The Cons: High "Entry Fee." A high-quality steel mold can cost between $5,000 and $50,000 upfront. Furthermore, die-cast parts usually have slightly lower structural density and a rougher surface finish than CNC-machined parts.

Best For: Mass-market consumer electronics, smart home sensors, and automotive components.

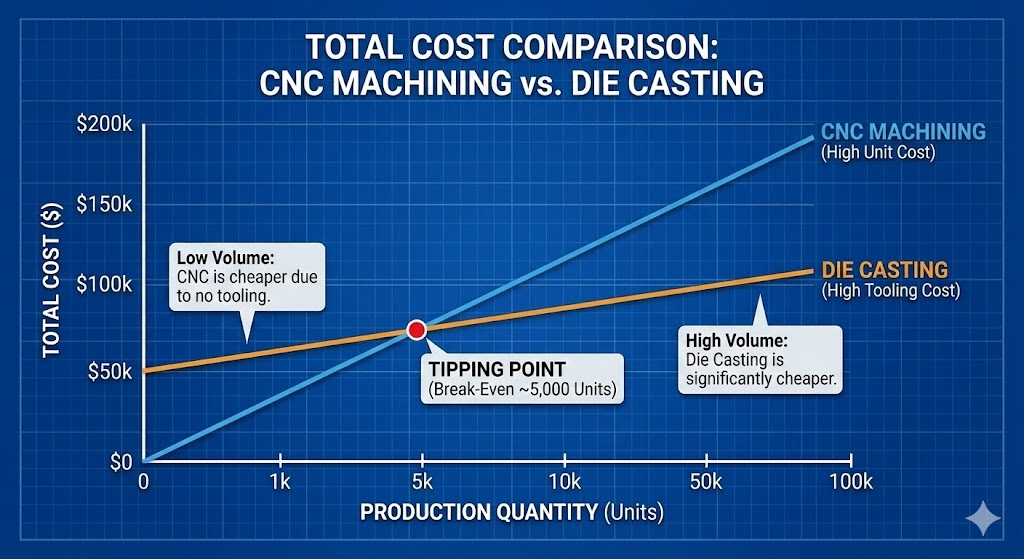

3. The "Tipping Point" Analysis

Where exactly does Die Casting become cheaper than CNC? In the industry, we call this the Break-Even Point.

As shown in the graph, the total cost (C) can be simplified as:

C = T + (U x Q)

Where:

T = Tooling/Setup Cost

U = Unit Cost

Q = Quantity

For CNC, T is near zero, but U is high. For Die Casting, T is very high, but U is very low. For a standard 3C enclosure, the "tipping point" is usually between 3,000 and 5,000 units. By the time you reach 100,000 units, Die Casting can save you up to 60-70% in total production costs.

4. The Coboggi "Hybrid" Approach

You don't always have to choose one or the other. Many of our most successful clients use a Hybrid Process:

Die Cast the Blank: We create the general shape of the enclosure using a high-speed die-casting mold.

CNC Post-Processing: We then move the part to a CNC machine to mill only the critical areas—like O-ring grooves, screw threads, and aesthetic edges.

This gives you the cost-savings of Die Casting with the precision of CNC.

5. Factors Beyond Price

Before you commit to a mold, consider these two factors:

Design Maturity: If you expect to change the port layout or button placement in six months, stay with CNC. Molds are permanent; changing a die is expensive.

Wall Thickness: Die casting allows for thinner walls (down to 1.5mm) than machining, which can reduce the overall weight of your device.

Conclusion: Scale Smartly

Choosing between CNC and Die Casting isn't just about the price today; it’s about your product’s roadmap. If you are aiming for 100k+ units, Die Casting is almost certainly your path to profitability—provided your design is locked and loaded.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish