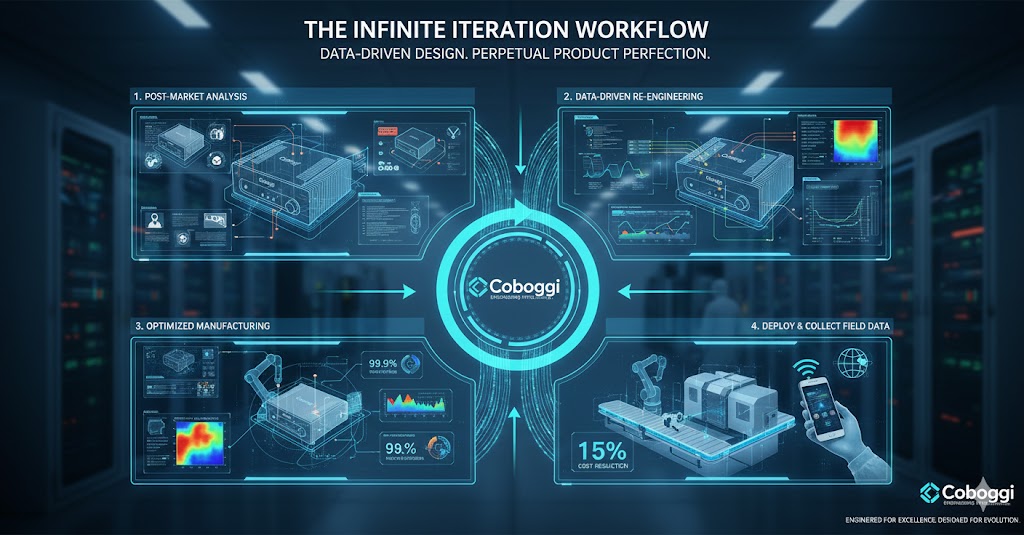

The most successful hardware brands don’t treat a product launch as the "finish line."

In the Coboggi ecosystem, the completion of a major production cycle is actually the start of a massive data-collection exercise.

The Infinite Feedback Loop is the process of taking real-world performance data, manufacturing logs, and customer sentiment to "harden" your product for future iterations. This is how a high-quality device evolves into a market-defining icon.

1. Post-Market "Battle Testing"

Once units are in the hands of thousands of customers, we look for "Field Data" that no laboratory can replicate.

The Analysis: How is the anodizing holding up in diverse climates? How does the Haptic Density (#46) feel after a year of daily use?

The Engineering Pivot: If field data suggests a specific design element can be strengthened, we adjust the specifications for the next run. We don't just solve problems; we prevent them in the next generation.

2. Efficiency Optimization (The 1% Gains)

During the scaling phase, our AI-integrated systems monitor every second of the manufacturing process.

The Data: We analyze tool wear patterns and "idle" machine time.

The Optimization: By refining a tool path to save just a few seconds per unit, we can save hundreds of hours across a full production cycle.

The Business Impact: These efficiencies allow you to increase your profit margins on future runs without having to raise prices for your customers.

3. Closing the "Serviceability" Gap

Real-world usage teaches us how a product is actually repaired, refurbished, or recycled.

The Learning: If the feedback from your Disruptive Pricing Models (#53) shows that refurbishing units for secondary life takes too long, we redesign the internal mounting points.

The Goal: We make the next version "Modular by Design." Faster serviceability lowers your long-term costs and supports a truly circular economy as outlined in the ESG Competitive Edge (#56).

4. Setting the Stage for Market Dominance

The feedback loop allows a brand to answer the most important question: What comes next?

Evolutionary Change: Small, data-driven tweaks that improve reliability and cost-efficiency.

Revolutionary Change: Identifying "feature gaps" that customers are asking for, which can then be engineered into the next aluminum chassis.

The Result: You stay ahead of the competition because by the time they've copied your first version, you are already shipping a perfected, next-generation iteration.

Conclusion: The Circle of Excellence

At Coboggi, we believe that precision is a moving target. The Infinite Feedback Loop ensures that your brand never stagnates.

Every unit shipped is a teacher, and every production run is a smarter, leaner, and more profitable version of the last.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish