In the Personal Care and Home Goods space, the "open/close" experience defines the product's perceived quality. A lid that grinds when screwed on feels cheap; a battery door that wiggles feels unfinished.

The Perfect Closure is about using CNC precision to create joins that feel effortless and secure.

At Coboggi, we focus on three primary mechanical joins that elevate the user experience.

1. The "Liquid" Thread (Precision Machined Lids)

For high-end skincare jars or electronic canisters, the screw-on motion should feel like it’s gliding on oil.

The Engineering: Instead of "rolled" threads used in cheap tins, we CNC-turn the threads. This ensures a constant pitch and zero "burrs."

The Benefit: It eliminates the "gritty" feel of metal-on-metal. When paired with a dampened liner, the lid comes to a soft, definitive stop, signaling a perfect seal every time.

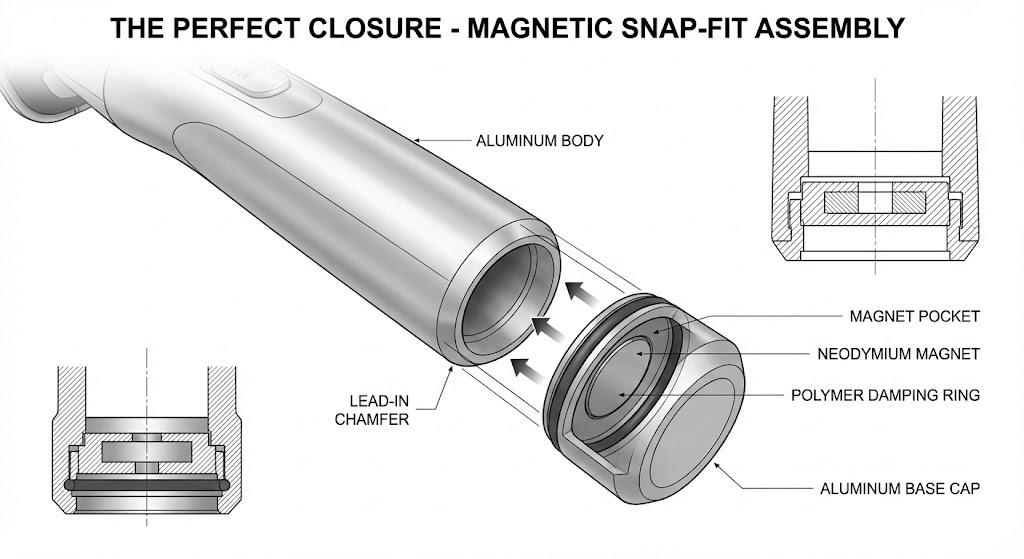

2. The Magnetic Snap (Zero-Force Latches)

Magnets are the "magic" of modern hardware. They allow for a clean, fastener-free exterior.

The Strategy: We machine internal "pockets" into the aluminum body to house N52 Neodymium magnets.

The Experience: For a trimmer’s battery door or a home hub’s cable cover, the magnets provide a "self-homing" effect. As the user brings the parts close, the metal snaps into place with a crisp, audible "thud" that feels much more premium than a plastic tab.

3. The "Interference" Snap-Fit

Unlike plastic, which is flexible and can "click" easily, aluminum is rigid. Creating a snap-fit requires extreme precision.

The Execution: We use a combination of a CNC-milled undercut and a high-performance polymer ring (like an O-ring or a POM clip) hidden inside the assembly.

The Result: This creates a "friction-lock" that requires a specific amount of force to open. It gives the user a sense of "mechanical security"—the part feels like it belongs exactly where it is.

4. Cross-Threading Prevention (The Lead-In)

Nothing ruins a premium experience faster than a lid that gets stuck because it was screwed on crooked.

The Coboggi Solution: We engineer a "Lead-In Chamfer" or a "Blunt Start" thread.

The Impact: This automatically aligns the lid as soon as it touches the base. It’s a small detail that ensures the user never feels frustrated, reinforcing the product’s status as a high-end tool.

Here is how these mechanical joins apply to your specific product lines:

A. Personal Care: The Ritual of Precision

In this space, closures are about hygiene, portability, and the tactile "click" of a morning routine.

Trimmers & Shavers: * Magnetic Battery/Charging Caps: Instead of a plastic door that snaps off, a magnetic aluminum end-cap feels indestructible.

Magnetic Blade Guards: Protecting the foil or blade with a "self-homing" magnetic cover that snaps into place regardless of how the user aligns it.

Luxury Skincare & Grooming: * CNC-Threaded Jars: For high-end pomades or eye creams. A weighted aluminum lid with "Liquid Threading" feels significantly more expensive than a standard plastic or thin-tin screw cap.

Travel Canisters: Precision-fit aluminum tubes for solid colognes or safety razors that use an O-ring friction fit to stay airtight and secure in a gym bag.

B. Home Goods: The "Heirloom" Experience

For home products, closures are about permanence and the satisfaction of a "soft-landing" mechanical stop.

Scent & Ambiance:

Weighted Candle Lids: Using a heavy aluminum lid with a hidden silicone gasket to create a "vacuum seal" that snuffs out the candle without smoke escaping.

Reed Diffuser Bases: A snap-fit aluminum collar that hides the glass bottleneck, turning a utility item into a piece of decor.

Smart Home Sensors: * Twist-Lock Bases: Instead of a sticky-pad base, a CNC-milled aluminum "bayonet mount" (like a camera lens) for wall-mounted sensors or cameras. It communicates that the device is a serious piece of technology.

C. Consumer Electronics: The Logic of Access

In electronics, closures often protect the "guts" of the device or provide access to ports and batteries.

Remote Controls & Handhelds:

Magnetic Battery Plates: A seamless aluminum back panel that uses magnets instead of a plastic "tab and slot." It eliminates the "creak" felt when squeezing a remote.

Modular Attachments:

Snap-Fit End Caps: For power banks or portable SSDs. Using a hidden snap-fit allows for a "fastener-free" design where no screws are visible, keeping the Visual Signature (#61) clean.

Charging Docks:

Alignment Guides: Using magnets to pull the device into the exact charging pins, providing haptic feedback that the connection is made.

Why it matters for your brand:

| Feature | User Perception | Brand Value |

| Magnetic Snap | "Magic" and High-Tech | Innovation & Luxury |

| CNC Threading | Substantial and "Real" | Quality & Longevity |

| Interference Fit | Precise and Secure | Engineering Excellence |

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish