I. Introduction: The Enclosure Imperative

In the world of electronics, the enclosure is often an afterthought, viewed simply as the "box" that contains the sensitive components. However, for serious industrial, medical, and aerospace applications, the enclosure is a critical performance component—it dictates the device's lifespan, thermal efficiency, and electromagnetic compatibility (EMC).

This is where aluminum has secured its reputation as the gold standard. It offers an unparalleled balance of thermal, structural, and electromagnetic properties. This guide is designed to help engineers and procurement specialists navigate the complexities of aluminum alloys, specifically focusing on how to select the precise material to ensure your OEM/ODM project meets its most stringent technical requirements.

II. Why Aluminum is the Gold Standard for Electronics

Aluminum alloys are favored over steel or plastic for electronic housings due to several synergistic properties:

A. Thermal Management (Heat Dissipation): Electronic components generate heat, which is the primary cause of system failure. Aluminum's high thermal conductivity (especially 6061 ≈ 167 W/m*K) allows the enclosure itself to act as a heat sink, efficiently drawing thermal energy away from the internal components and dissipating it into the environment.

B. EMI/RFI Shielding (The Faraday Cage): Modern environments are saturated with radio frequency (RF) and electromagnetic interference (EMI).As a highly conductive metal, aluminum inherently forms a Faraday Cage, effectively blocking external interference from disrupting sensitive circuitry and preventing internal noise from leaking out.This is a non-negotiable requirement for compliance in industries like Telecom and Medical Devices.

C. Strength-to-Weight Ratio: In applications ranging from handheld diagnostics to satellite equipment, weight is a critical factor. Aluminum offers a fantastic strength-to-weight ratio, providing robust protection against impact and vibration while being significantly lighter than steel.

D. Natural Corrosion Resistance: When exposed to air, aluminum spontaneously forms a thin, tough layer of aluminum oxide Al2O3 on its surface. This passive layer acts as a natural protective barrier against corrosion, which can then be enhanced through subsequent finishing processes.

III. Deep Dive: Key Aluminum Alloy Series for Enclosures

The vast majority of electronic enclosures are fabricated from alloys in the 5000 or 6000 series, each optimized for different manufacturing methods and application demands.

A. The 6000 Series (Magnesium and Silicon): The Machining Workhorse

The 6000 series, particularly 6061-T6, is the most commonly specified general-purpose aluminum alloy. Its popularity stems from its unique ability to be heat-treated (T6 temper), achieving a high ultimate tensile strength (~310\MPa), which is critical for structural integrity.

Ideal for: Enclosures fabricated via CNC machining or extrusion. Its elemental composition allows for excellent chip break, yielding superior surface finishes (low Ra values) and minimizing tooling wear—a vital factor in precision manufacturing.

Key Property: High strength and superior machinability.

B. The 5000 Series (Magnesium): The Sheet Metal Specialist

The 5000 series alloy 5052-H32/H34 is a non-heat-treatable alloy that gains its strength through work hardening (H-tempers). Its defining characteristic is its high content of magnesium, which makes it an exceptional choice for demanding environmental and fabrication requirements.

Ideal for: Enclosures fabricated via sheet metal forming, bending, and welding.

Key Property: Superior weldability and excellent resistance to corrosion, especially in moisture-laden or saltwater environments, making it the preferred choice for outdoor utility boxes and marine electronic gear. Its higher fatigue strength also makes it robust against repeated vibration and cyclic loads.

IV. Critical Selection Factors: 6061 vs. 5052 Comparison

While hundreds of aluminum alloys exist, for electronic enclosures, the decision often narrows down to the 6061 and 5052 series. The "best" choice is not about superior strength, but about aligning the material properties with the manufacturing process, application environment, and cost targets.

| Factor | 6061 Aluminum (T6 Temper) | 5052 Aluminum (H32/H34 Temper) | Selection Insight |

| Primary Strength | Higher (Yield Strength ~276\MPa ) | Moderate (Yield Strength ~ 193 \MPa) | Choose 6061 for high-stress structural parts. |

| Machinability | Excellent (Favorable chip break) | Fair to Poor (Gummy, higher tooling wear) | Choose 6061 for complex CNC machining. |

| Weldability | Good, but strength loss in HAZ; requires heat treatment post-weld. | Superior (Best weldability of common alloys) | Choose 5052 for welded sheet metal assemblies. |

| Corrosion Resistance | Good, but inferior to 5052 in chloride-rich environments. | Excellent (Due to higher Mg content) | Choose 5052 for harsh, outdoor, or marine use. |

| Thermal Conductivity | Higher ~167 \W*m} \ K | Lower ~138 \W*m\K | Choose 6061 for applications requiring maximum heat dissipation. |

Key Takeaways for Procurement:

For Machining & Heat Sinks: If your design features complex geometries requiring precise CNC machining, or if the application involves significant heat generation, the 6061-T6 alloy is the default choice.

For Sheet Metal & Outdoors: If the enclosure is primarily fabricated via bending, stamping, or welding, and especially if it will face salt, moisture, or chemical exposure, 5052-H32/H34 offers superior formability and corrosion defense.

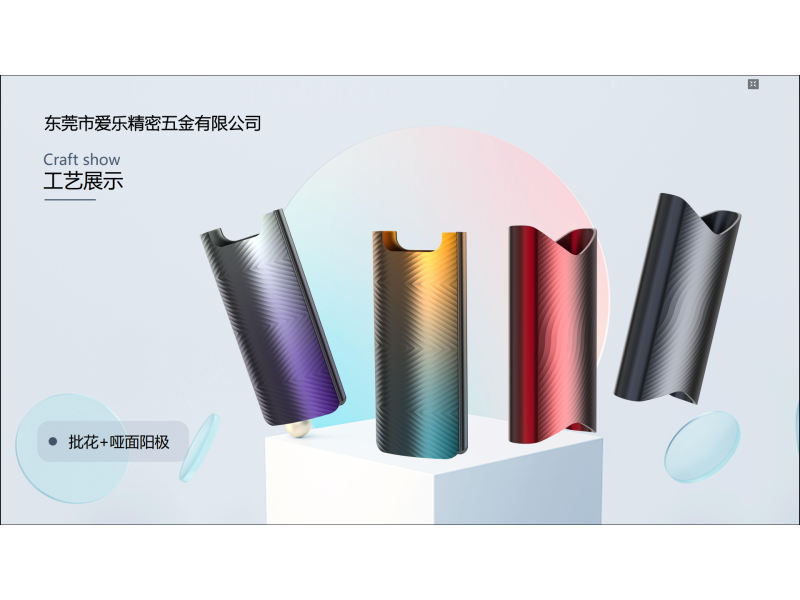

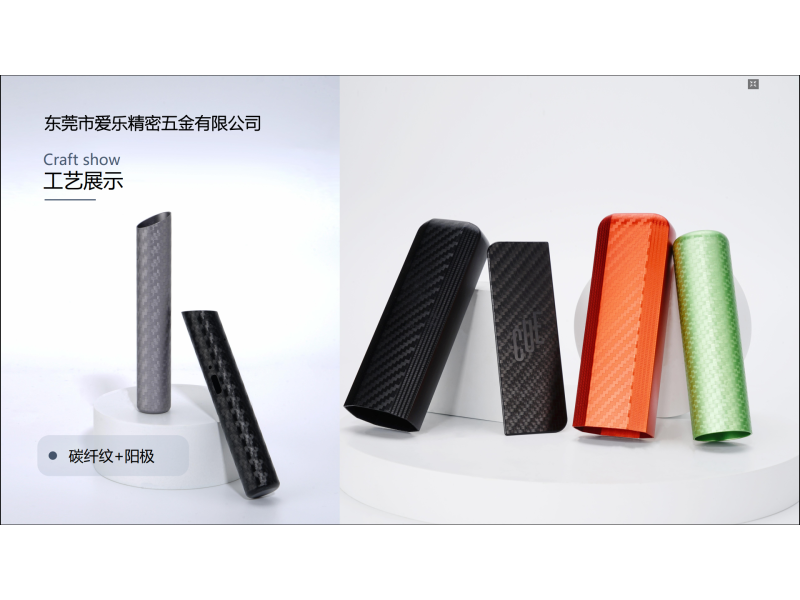

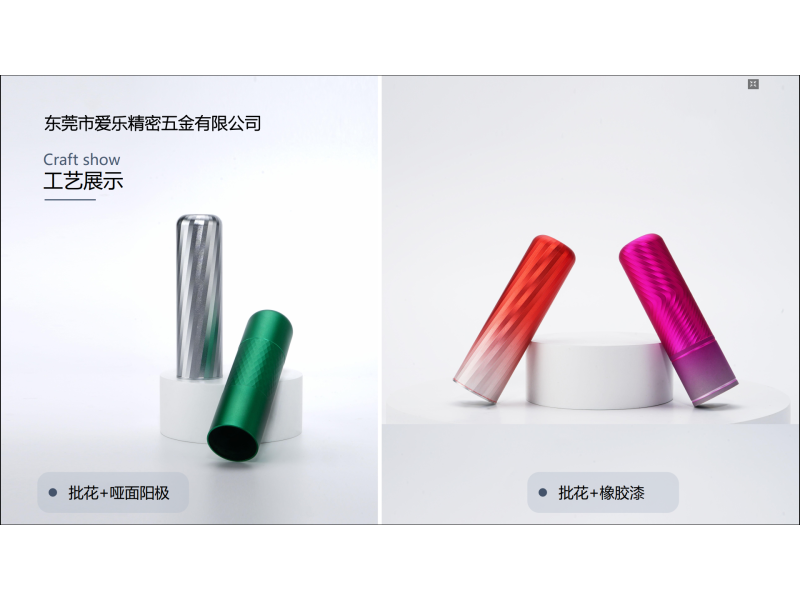

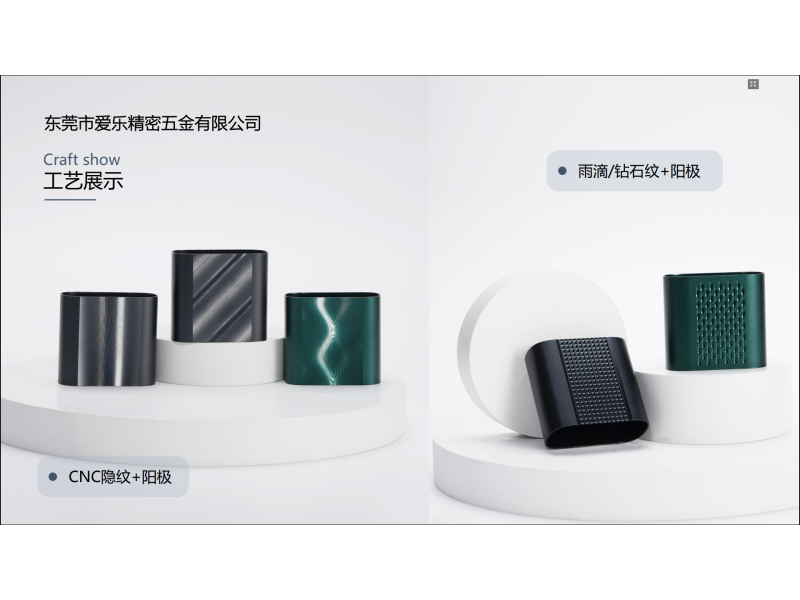

V. Surface Finishes: Enhancing Protection and Aesthetics

The alloy provides the base material properties, but the surface finish determines the final product's durability, tactile feel, and aesthetic appeal. Choosing the right finish is an integral part of the OEM/ODM specification.

A. Anodizing (Type II & III)

Anodizing is an electrochemical conversion process that significantly thickens the naturally occurring aluminum oxide layer. This layer is hard, porous, and highly resistant to wear.

Type II (Standard/Sulphuric): Provides a clean, cosmetic finish in various colors. It is primarily used for improved corrosion resistance and durability on consumer and light industrial enclosures.

Type III (Hardcoat): Achieved by running a higher current density at a lower temperature. This creates a much thicker, harder ceramic-like layer that offers superior abrasion and wear resistance. It is essential for parts exposed to extreme friction or high-contact industrial environments.

B. Powder Coating

Powder coating is a dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto the enclosure. The part is then cured under heat, causing the powder to melt and flow into a continuous, tough film.

Aesthetic Versatility: Offers the widest range of colors, textures, and sheen levels, which can be crucial for branding or device differentiation.

Impact Resistance: Provides an exceptionally durable, chip-resistant coating that is generally thicker than liquid paint, offering excellent impact resistance and masking minor cosmetic defects in the base metal.

Environmental Benefit: The process uses no solvents and releases negligible volatile organic compounds (VOCs).

VI. Conclusion: Partnering on Precision

Selecting the right aluminum alloy—whether it's the high-strength, thermally efficient 6061 or the corrosion-resistant, weldable 5052—is a nuanced decision that affects every stage of manufacturing, from machining efficiency to final product longevity. The choice must be a calculated function of the component's thermal budget, mechanical loads, environmental exposure, and required aesthetic.

At Aile Precision Hardware (coboggi.com), we specialize in premium OEM/ODM services, translating complex engineering requirements into high-quality aluminum enclosures. We don't just execute your design; we partner with you to validate the material selection and process (CNC, sheet metal, casting) to ensure optimal performance and cost-efficiency.

Ready to move from concept to mass production? Contact our engineering team today to discuss your project's specific material needs and discover the precision difference.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish