The 3C industry is the most unforgiving arena for aluminum manufacturing.

Consumers demand devices that are impossibly thin, yet they expect them not to bend in a pocket or crack upon impact. At Coboggi, we solve this "Paradox of 3C" through a combination of aerospace-grade alloys and micro-precision machining.

1. Material Selection: The 7000 Series Revolution

While 6061 aluminum is the industry standard, flagship 3C products (like high-end smartphones and smartwatches) have migrated to the 7000 series (Zinc-alloyed).

High Yield Strength: 7000 series aluminum offers nearly double the strength of 6000 series. This allows us to machine wall thicknesses down to 0.4mm or 0.5mm without sacrificing structural integrity.

Hardness: It resists dents and scratches better, ensuring the device looks "new" for a longer lifecycle.

2. The Thermal Challenge: Metal as a Heat Sink

As processors become more powerful, heat is the enemy of performance. In a 3C enclosure, the aluminum body serves as a passive cooling system.

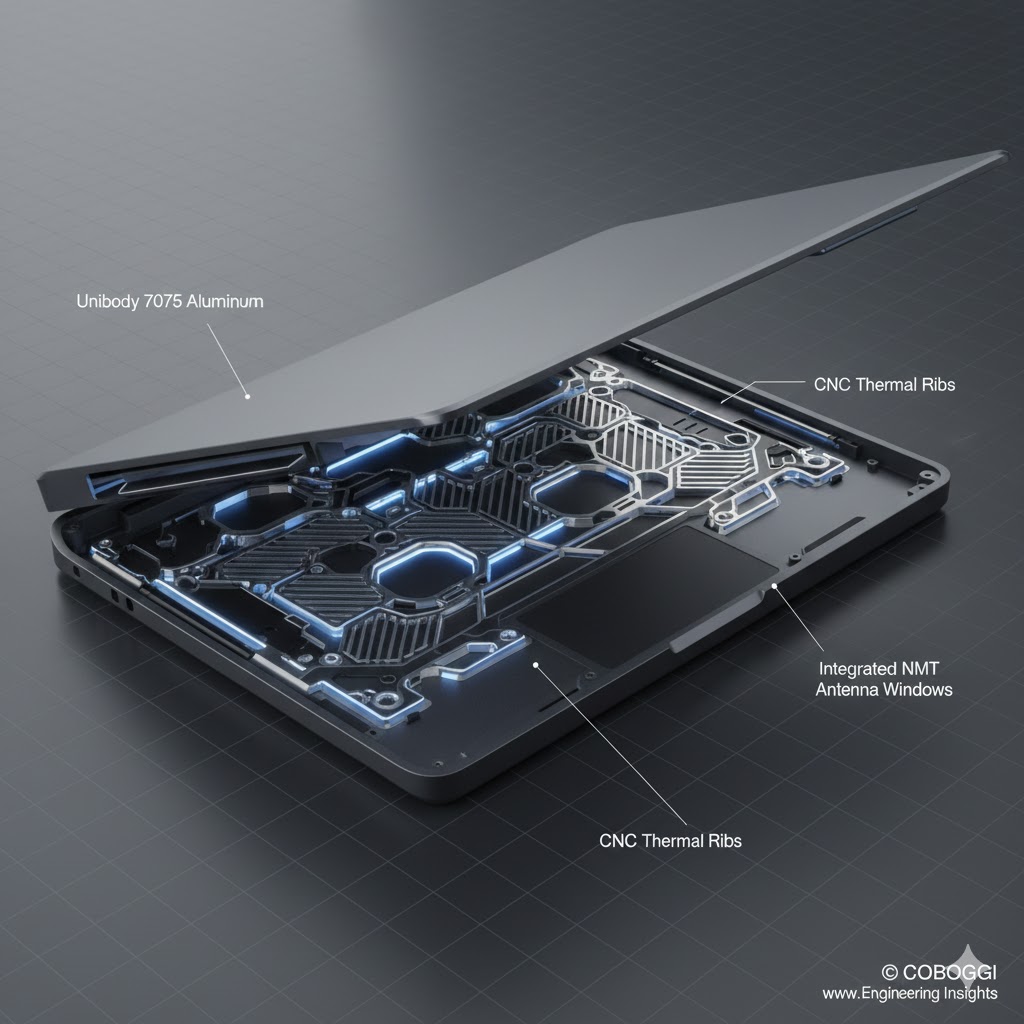

Internal Finning: We often machine micro-grooves or "heat pillars" directly into the internal face of the aluminum shell to increase surface area for heat dissipation.

Integrated Heat Spreaders: By CNC-milling the enclosure and the internal support structure from a single "unibody" block, we create a direct thermal path from the CPU to the outside air.

3. Nano-Molding Technology (NMT)

A 3C device cannot be 100% metal; it needs "windows" for 5G, Wi-Fi, and Bluetooth signals.

The Process: We chemically etch microscopic "T-pores" into the aluminum, then injection-mold high-performance plastic directly into the metal.

The Result: A seamless, waterproof bond between metal and plastic that maintains the structural strength of a single piece while allowing for perfect signal transparency.

4. Achieving the "Zero-Gap" Aesthetic

In 3C design, the "split lines" between the aluminum frame and the glass screen or the port inserts must be nearly invisible.

Tolerance Control: Coboggi maintains a tolerance of ±0.01mm on 3C enclosures. This ensures that when the glass meets the metal, the transition is felt as a single, continuous surface by the user's thumb.

Secondary CNC: After anodizing, we often perform a final high-speed CNC pass to clear out the ports (USB-C, speakers) to ensure "Sharp-Edge" precision that molded parts can't match.

5. Finishing for the Hand

Because 3C devices are touched hundreds of times a day, the finish must be "Skin-Friendly":

Fine Sandblasting (No. 180-220): Creates a soft, "silk-like" matte finish that resists fingerprints.

Oleophobic Anodizing: We apply specialized seals to the anodic layer that repel skin oils, keeping the device looking clean even after heavy use.

Conclusion: The Unibody Standard

The 3C enclosure is no longer a simple box; it is a complex piece of thermal and structural engineering. At Coboggi, we provide the 7-series alloy expertise and NMT integration required to build the world's next "must-have" flagship.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish