In the world of high-end audio, designers face a paradox: the equipment must be incredibly strong to withstand constant use, yet lightweight enough for hours of comfortable wear.

For professional headphones, portable DACs, and high-fidelity monitors, the choice of aluminum alloy is the most critical decision in the design phase.

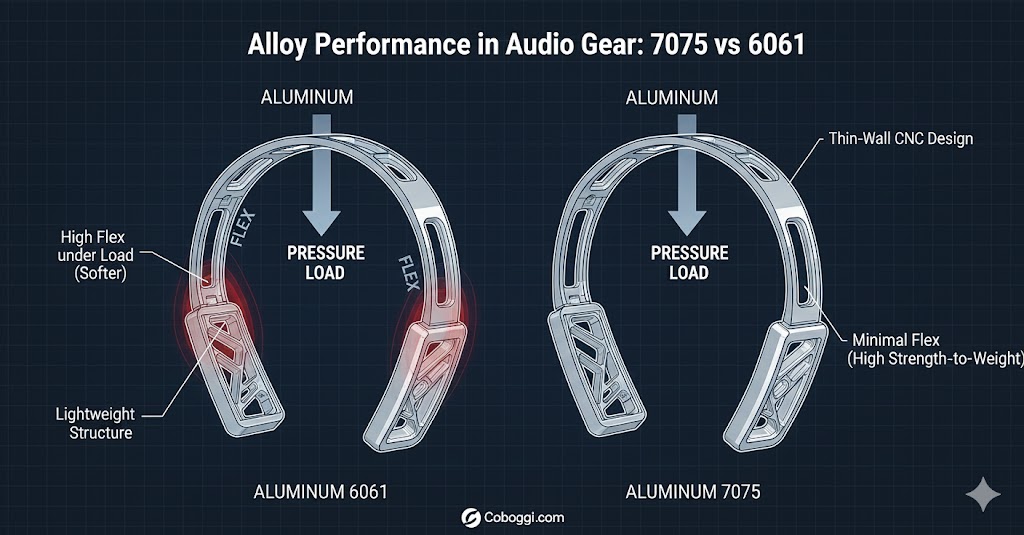

While Aluminum 6061 is the workhorse of the industry, Aluminum 7075 is increasingly becoming the "holy grail" for flagship audio products. Here is how they compare in the high-stakes world of sound.

1. The Power of 7075: Strength-to-Weight King

Aluminum 7075 is often referred to as "Aerospace Grade" because its strength is comparable to many types of steel, yet it retains the lightness of aluminum.

The Audio Advantage: For high-end headphones, using 7075 allows engineers to thin out the walls of the ear-cup or the headband suspension.

The Result: You get a chassis that is virtually indestructible but weighs 30% less than a 6061 counterpart of the same structural rigidity. In the audio world, a few grams can be the difference between a headset that feels "heavy" and one that feels "invisible."

2. 6061: The Master of Dampening and Finish

While 7075 wins on pure strength, 6061 remains the king of versatility.

Vibration Control: Aluminum 6061 has slightly different acoustic properties. Its molecular structure provides excellent internal dampening, which is crucial for speaker housings and amplifier chassis where "ringing" or unwanted resonance must be avoided.

The Aesthetic Finish: 6061 is easier to anodize to a mirror-like or deep satin finish. For audio gear that needs to look like a piece of jewelry sitting on a desk, 6061 provides a more consistent, "rich" color depth.

3. Technical Breakdown: The Hard Numbers

| Property | Aluminum 6061-T6 | Aluminum 7075-T6 |

| Tensile Strength | ~310 MPa | ~572 MPa |

| Yield Strength | ~276 MPa | ~503 MPa |

| Machinability | Excellent | Good |

| Best For | Desktop DACs, Speaker Bezels | Pro-Headphones, Moving Parts |

4. Why "Thin-Wall" CNC is the Future

Modern audio design is moving toward "skeletonized" structures—frames that have been hollowed out to save weight without losing strength.

Coboggi’s Precision: Working with 7075 requires high-speed spindles and incredibly sharp tooling to prevent the material from "gumming." Our CNC capabilities allow us to machine walls down to 0.8mm in 7075, creating audio frames that are as light as carbon fiber but with the premium, cold-to-the-touch feel of metal.

Conclusion: Choosing Your Sound

If your product is a stationary desktop amplifier, 6061 offers the best balance of cost and finish. However, if you are building the world’s next great pair of professional monitors or a portable hi-res player, the strength-to-weight ratio of 7075 is an investment that users will feel—literally—every time they pick it up.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish