The wearable market—comprising smartwatches, fitness bands, and even smart rings—is no longer just about steps and calories.

These are now sophisticated medical-grade instruments. However, because these devices live in constant contact with human skin, they face a unique engineering hurdle: Biocompatibility.

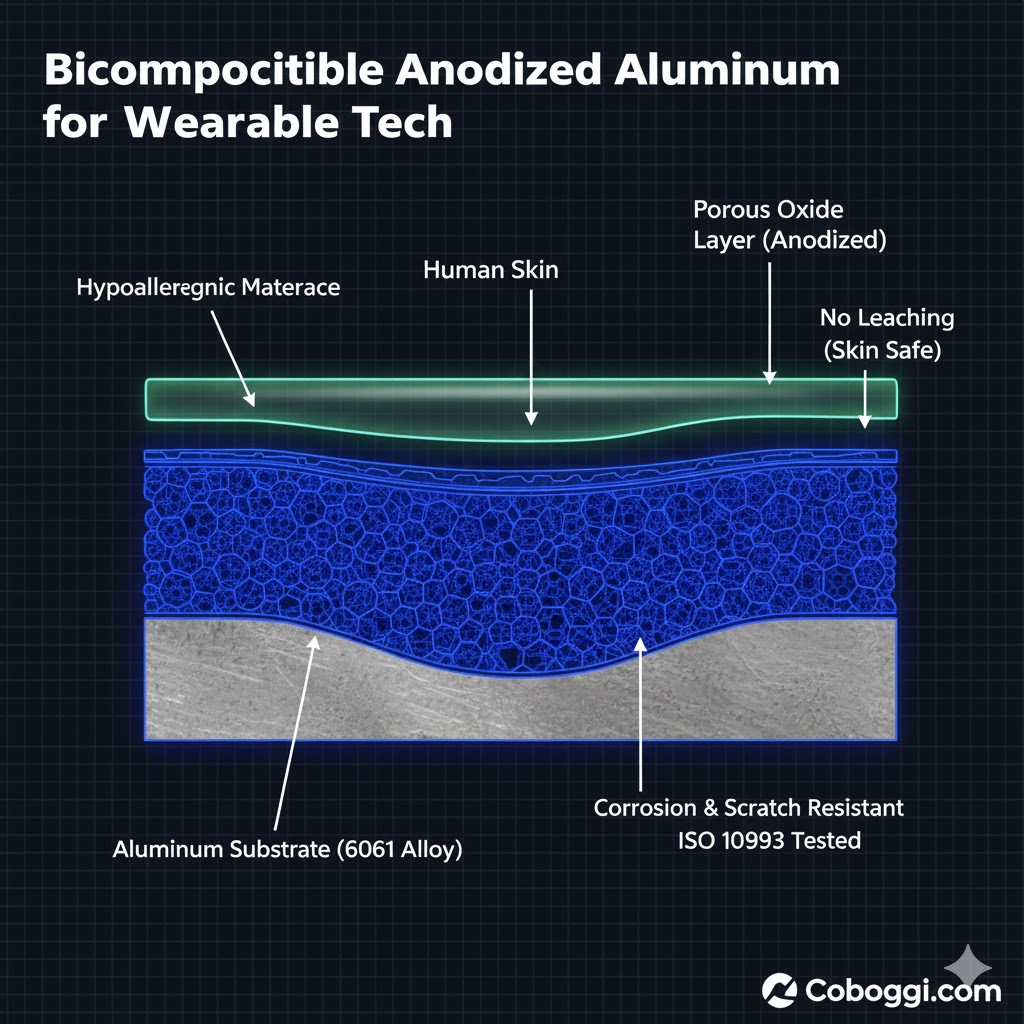

If the metal housing of a tracker causes a rash or leaches chemicals into the skin, the product is a failure, regardless of how accurate its sensors are. At Coboggi, we help brands bridge the gap between "industrial-strength" and "skin-safe."

1. The Nickel Problem and the Aluminum Advantage

Many traditional metal alloys (like certain stainless steels) contain nickel, a common allergen that causes contact dermatitis.

Why Aluminum? Aluminum is naturally hypoallergenic. It is highly resistant to the "leaching" of heavy metals.

The Weight Factor: In wearables, every gram matters. Aluminum offers the structural protection of metal at a weight that feels "invisible" on the wrist or finger.

2. Anodizing as a Biocompatible Barrier

Raw aluminum is rarely used in wearables; it is almost always anodized. Anodizing creates a controlled oxide layer that is integrated with the metal substrate.

Type II Anodizing: This is the standard for wearables. It allows for a vast array of "jewelry-grade" colors while creating a non-reactive ceramic surface.

The Importance of Sealing: After anodizing, the microscopic pores of the aluminum must be "sealed." Coboggi uses high-purity deionized water sealing or specialized salt sealing to ensure no dyes or chemicals can migrate out of the finish and onto the user's skin.

3. Meeting ISO 10993 Standards

For devices marketed as "health-trackers" or medical devices, the housing must often pass ISO 10993 testing. This involves:

Cytotoxicity: Ensuring the material doesn't kill cells.

Sensitization: Ensuring the material doesn't cause allergic reactions over time.

Irritation: Ensuring the surface texture and chemistry don't irritate the skin.

At Coboggi, we work with certified material suppliers to ensure our Aluminum 6061 and 7075 alloys meet the baseline requirements for these rigorous tests.

4. Surviving the "Human Environment"

Human skin is a surprisingly harsh environment. It produces sweat, which is a mix of water, salts, and acids (low pH).

Corrosion Resistance: Sweat can cause "pitting" in lower-quality metals. Our hard-anodizing processes ensure that the finish remains pristine even after months of high-intensity workouts and constant moisture exposure.

Oleophobic Coatings: For wearables, we often suggest an additional AF (Anti-Fingerprint) coating over the anodized aluminum. This prevents skin oils from staining the metal and makes the device easier to clean.

5. Comparison: Wearable Material Options

| Material | Skin Safety | Weight | Durability | Aesthetic Versatility |

| Plastic/Polymer | High | Ultra-Light | Low | Low (Feels Cheap) |

| Stainless Steel | Risk (Nickel) | Heavy | High | High (Mirror Finish) |

| Coboggi Aluminum | High (Hypoallergenic) | Light | High | Highest (Vibrant Colors) |

Conclusion: Beauty Without Compromise

The future of healthcare is wearable. By combining the lightweight strength of aluminum with biocompatible anodizing, Coboggi enables brands to build devices that are as safe for the body as they are powerful for the user.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish