When you look at a flagship smartphone or a high-end audio dial, you often see a thin, glittering line of bright metal tracing the perimeter.

This isn't just a "pretty line." It is a functional bevel, and its engineering is a Masterclass in balancing aesthetic "pop" with mechanical necessity.

At Coboggi, we treat the edge as a critical engineering zone. How we finish a corner dictates how the product feels in the hand, how it survives a drop, and how it catches the light on a retail shelf.

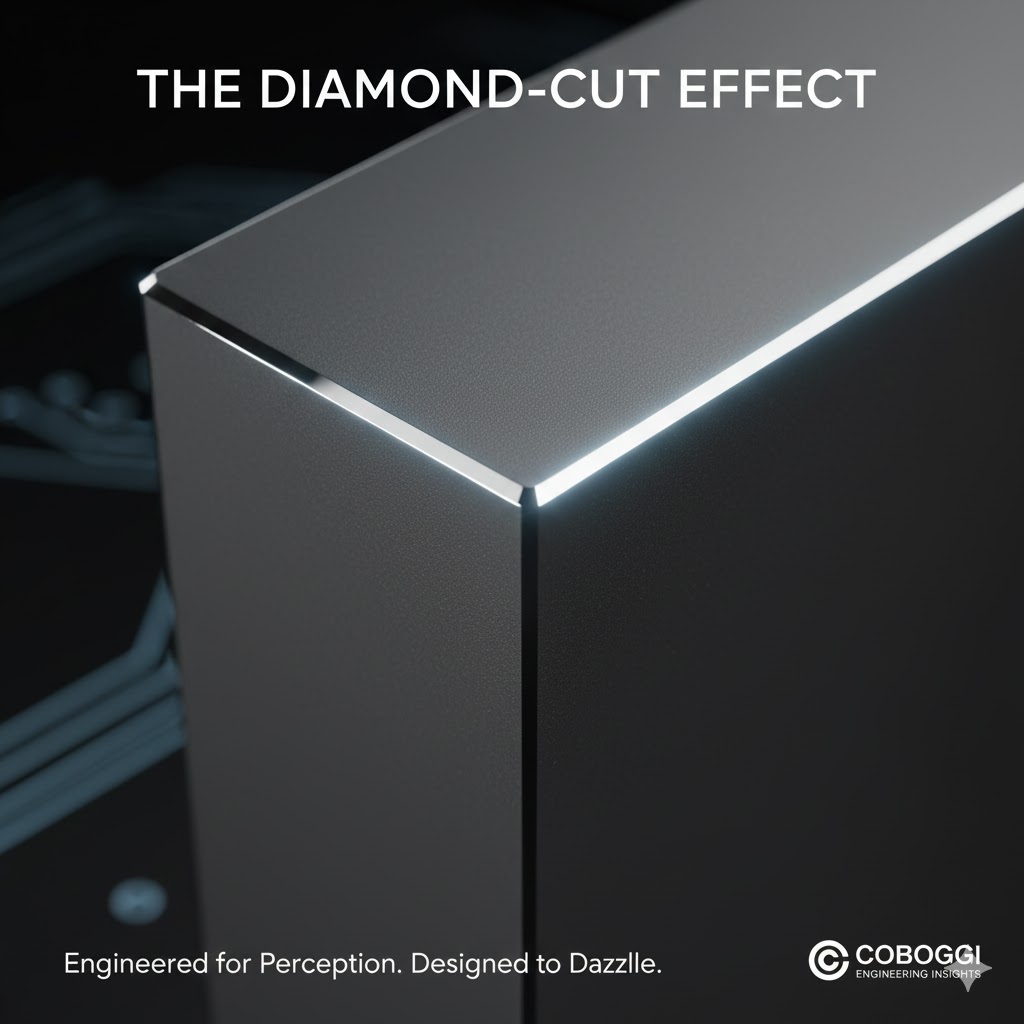

1. "Edge Light" Physics: The Visual ROI

Aluminum’s greatest aesthetic asset is its reflectivity. A flat surface reflects light in one direction, but a 45-degree chamfer (bevel) catches light from multiple angles.

The Strategy: By "Diamond-Cutting" a bevel after the anodizing process, we expose the raw, polished aluminum beneath the color.

The Result: This creates a "Halo Effect" that frames the product, making it look thinner and more precisely manufactured.

The Business Logic: This visual "glint" is a subconscious signal of CNC Precision. It tells the customer, "This wasn't poured into a mold; it was carved from a solid block."

2. Improving Anodizing "Build-Up" and Durability

Physics dictates that electrical charges concentrate at sharp points. In the anodizing bath, this causes the protective oxide layer to be thinner and more brittle on sharp 90-degree corners.

The Problem: Sharp edges are the first place the finish will "chip" or "flake" if the product is bumped.

The Coboggi Solution: We apply a Micro-Radius or a Technical Bevel to every corner.

The ROI: This allows the anodized layer to wrap smoothly around the edge, significantly increasing the "Impact Resistance" of the finish.

3. Haptic Safety: The "Burr-Free" Guarantee

In handheld devices or medical tools, a "sharp" edge isn't just a quality issue—it’s a liability.

The Engineering: We use Multi-Axis CNC Chamfering to ensure that every human-contact point is "Touch-Safe."

The "Necessary Money" Investment: While "Tumbling" (vibratory finishing) can dull edges cheaply, it rounds them inconsistently. Coboggi uses dedicated CNC toolpaths to ensure every bevel is mathematically identical.

The Value: The product feels "soft" to the touch despite being made of hard metal. This is the hallmark of premium ergonomics.

4. Preventing "Stress Risers"

In structural aluminum components, a sharp internal corner is a "Stress Riser"—a place where cracks are likely to start under pressure.

The Tech: We engineer Fillets (curved internal bevels) into every corner of the internal chassis.

The Benefit: This distributes mechanical stress across a wider area, making the entire housing 20-30% stronger without adding weight.

The Business Logic: You are engineering against "Catastrophic Failure," ensuring the device survives real-world drops and pressure.

Conclusion: The Difference is in the Decimals

A bevel might only be 0.5mm wide, but that half-millimeter carries the weight of your brand’s perceived quality.

By mastering the physics of the edge, Coboggi ensures your product is safer, stronger, and more visually striking than anything else on the market.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish