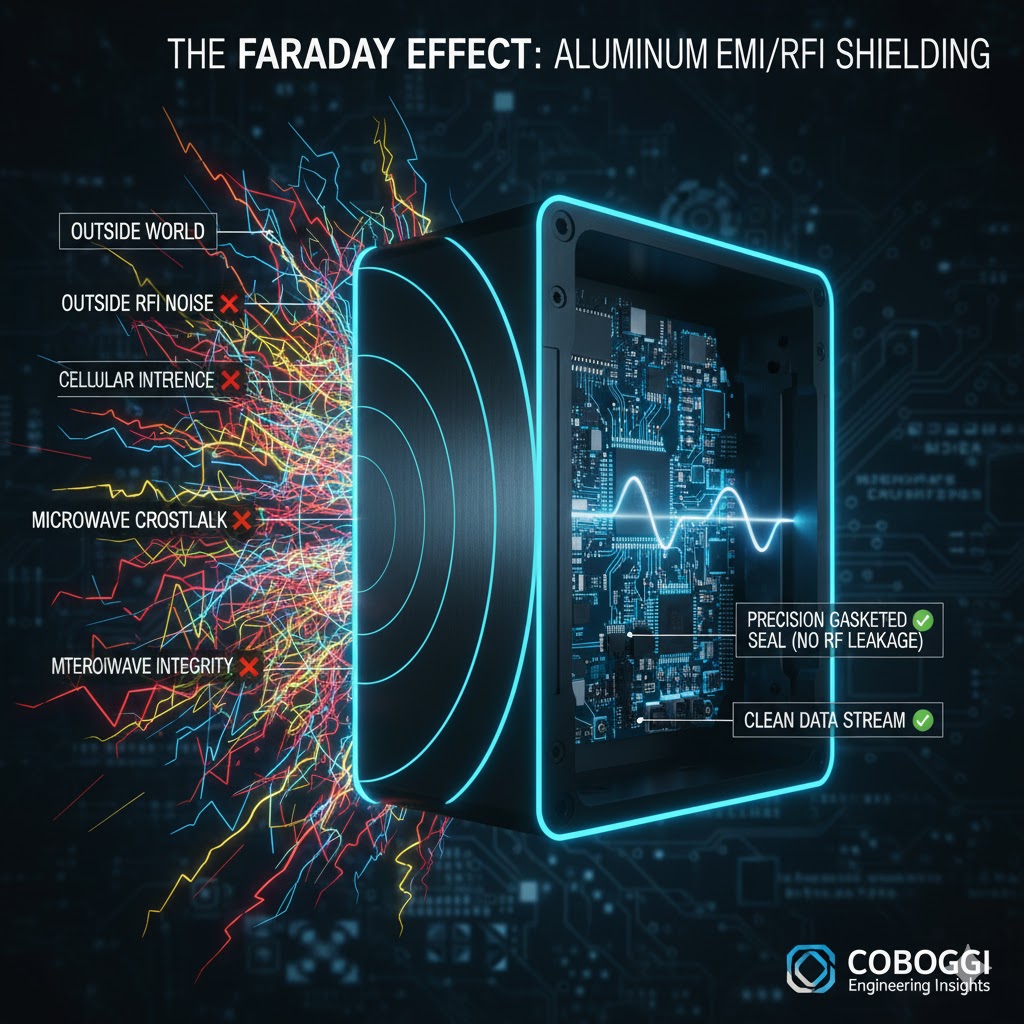

In the world of smart devices, IoT, and high-speed processors, "Noise" is a liability.

Every circuit board emits electromagnetic energy, and every board is vulnerable to it. If you house your electronics in plastic, you are forced to use expensive conductive sprays, metallic tapes, or internal "cans" to meet legal requirements.

At Coboggi, we advocate for the Integrated Shielding Strategy: utilizing the aluminum housing itself as a 360-degree Faraday Cage.

1. Native Conductivity: The "Free" Shield

Aluminum is a highly conductive material. A properly designed aluminum enclosure naturally blocks both incoming and outgoing interference.

The Cost of Failure: If your product fails FCC Part 15 or CE EMC tests, you face "Stop Ship" orders and expensive PCB redesigns.

The Coboggi Advantage: Because our CNC housings are one solid piece of metal, they provide superior shielding effectiveness (often >60dB) compared to plastic.

The ROI: You spend "Necessary Money" on the chassis to save "Emergency Money" on compliance testing and redesign cycles.

2. Precision Interfaces & Conductive Gaskets

A shield is only as good as its weakest link—usually the seams where two parts meet.

The Problem: If the fit between the top and bottom cover is loose, "RF Leakage" occurs.

The Tech: Coboggi machines tolerances to within microns, ensuring perfect metal-to-metal contact. We also design specific Gasket Grooves for conductive elastomers that ensure the electrical "loop" is never broken.

The Value: This precision ensures that your device remains "Silent" to regulatory sensors, speeding up your time-to-market.

3. Selective Anodizing: Keeping the "Ground" Alive

Anodizing is an insulator (it does not conduct electricity). To have a functional shield, the internal contact points must remain conductive.

The Engineering: Coboggi uses Selective Masking or Chemical Film (Chromate Conversion) on the interior of the chassis while providing a beautiful, hard-anodized finish on the exterior.

The Result: The device looks premium on the outside but maintains a perfect electrical ground on the inside.

The Business Logic: You get the best of both worlds—aesthetic beauty and high-level electrical engineering—without needing a secondary "Shielding" supplier.

4. Signal Integrity in the 5G Era

As frequencies get higher (5G, Wi-Fi 6E), shielding becomes harder. Plastic enclosures with thin metallic coatings often flake over time, leading to "Ghost Failures" in the field.

The Reliability Factor: An aluminum enclosure's shielding properties never degrade. It provides the same protection on Day 3,000 as it did on Day 1.

The ROI: This reduces "No Fault Found" (NFF) returns where a customer experiences glitchy behavior due to local interference (like being near a microwave or a cell tower).

Conclusion: Protecting Your Signal is Protecting Your Sales

EMI/RFI shielding is often invisible to the customer, but its absence is painfully visible in the form of failed launches and glitchy products. By choosing a precision aluminum enclosure from Coboggi, you are buying Regulatory Insurance. You are ensuring that your device performs perfectly in the messy, "noisy" real world, securing your brand's reputation for rock-solid reliability.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish