In a premium hardware ecosystem, the user’s eye and hand are the ultimate judges. A "Modular System" isn't just about parts that fit together; it’s about parts that belong together.

To achieve this, we must harmonize the three pillars of aluminum treatment: CNC Geometry, Laser Processing, and Anodizing.

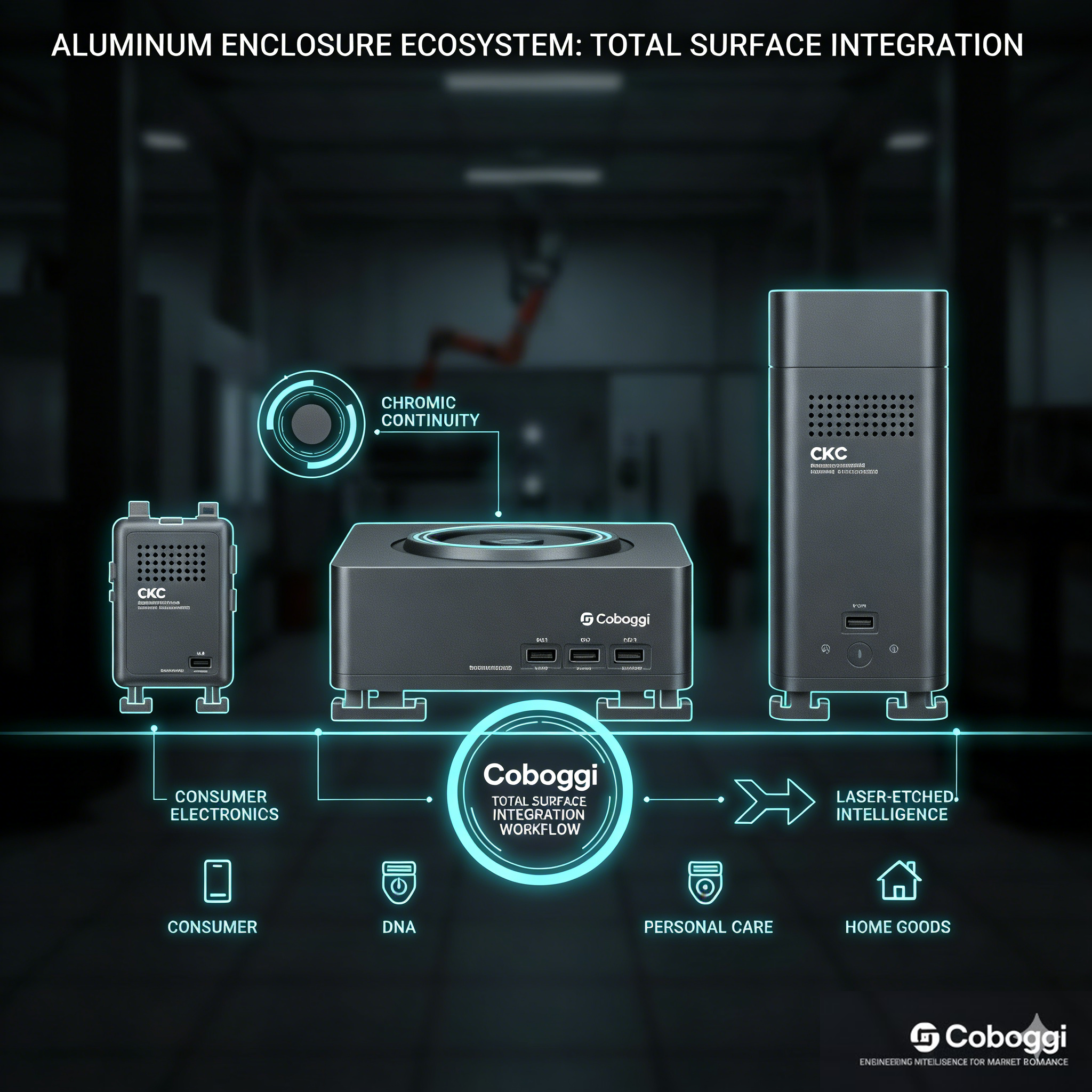

At Coboggi, we synchronize these processes to ensure your entire product line shares a single, unbreakable "Physical DNA."

1. Structural DNA (The CNC Foundation)

The "bones" of your ecosystem rely on shared machining logic.

The Strategy: We utilize standardized internal mounting grids and interlocking external geometries (stacking grooves, tongue-and-groove joints).

The Benefit: This allows different enclosures to physically nest together. By using a "Master Tooling" approach, we ensure that the tolerances for these joints are identical across every SKU in your library.

2. Chromic Continuity (The Anodizing Standard)

Anodizing is notoriously difficult to replicate across different alloys or batches. In an ecosystem, a 2% shift in color is a failure.

The Coboggi Solution: We use Spectrophotometric Color Matching and strict bath-chemistry controls to ensure that your "Signature Color" is identical across the entire ecosystem.

Surface Hardness: We maintain a consistent micron-thickness for the oxide layer, ensuring that every product in your line has the same scratch resistance and "cold-touch" feel. This is essential for maintaining the Haptic Density (#46) your customers expect.

3. Functional Identification (Precision Laser Processing)

Laser processing is where your enclosure gains its "Intelligence" and UI.

The Execution: We use high-speed fiber lasers to create unified branding, port labels, and technical specifications across the ecosystem.

Micro-Perforations: For enclosures requiring thermal management, we use lasers to create precision-drilled cooling patterns that match across the product line—turning a functional vent into a visual "Brand Signature."

The Edge: Because our lasers are calibrated to the same digital master file, a 0.5mm font on your smallest module will be indistinguishable from the same font on your rack-mount unit.

4. The Integrated Workflow: The "Coboggi Recipe"

An ecosystem fails when these three processes are treated as separate steps.

The Workflow: We design the CNC paths with the anodizing rack-points in mind, and we calibrate the laser settings based on the specific thickness of the anodized layer.

The Result: A perfectly flush, high-contrast finish where the laser-etched logo pops against a deep, consistent anodized surface, all contained within a precision-milled housing.

Conclusion: One Vision, Many Enclosures

A true Aluminum Enclosure Ecosystem is a symphony of engineering.

By integrating CNC, Laser, and Anodizing into a single, repeatable "Recipe," Coboggi allows you to scale your product line with the confidence that every new addition will feel like it was carved from the same block of metal as the first.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish