As IoT devices grow more powerful, they face a silent enemy: Heat.

Whether it’s an AI-driven security camera, a high-speed networking hub, or an industrial edge-computing sensor, internal components generate thermal energy that can degrade performance and shorten the device's lifespan.

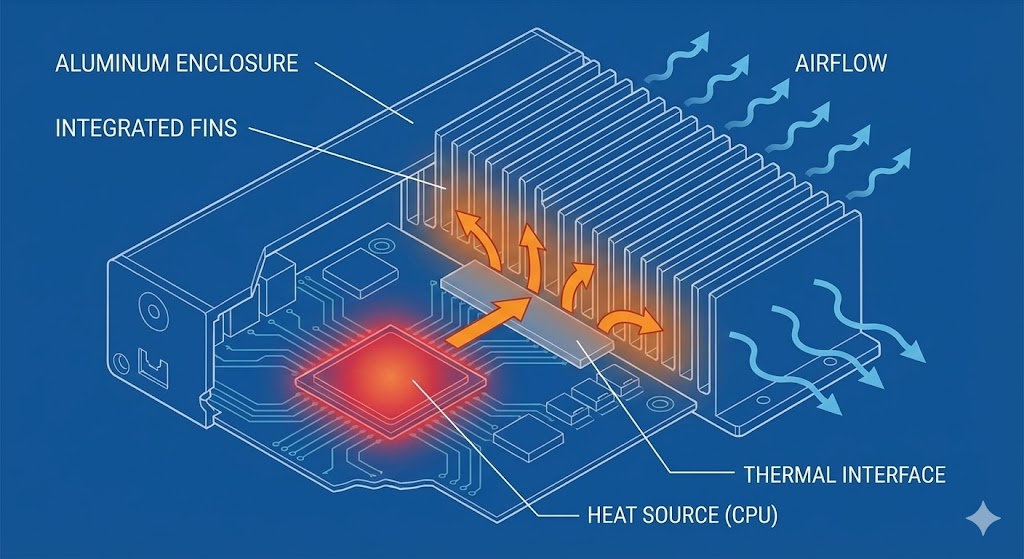

In the past, engineers relied on noisy, failure-prone fans. Today, the "Heat Sink Revolution" is moving toward passive cooling. By integrating the heat sink directly into the aluminum enclosure, brands can create silent, sleek, and indestructible devices. Here is how Coboggi helps you master thermal management through precision engineering.

1. Why Aluminum is the Ultimate Thermal Conductor

To understand the revolution, we must look at the physics. Thermal conductivity (k) measures a material's ability to transfer heat.

Plastic (Polycarbonate): k≈0.2$ W/m·K (An insulator that traps heat).

Aluminum (6061): k≈167$ W/m·K.

Aluminum is roughly 800 times better at moving heat than plastic. When your PCB is housed in a Coboggi aluminum enclosure, the entire "shell" of the device becomes a massive cooling surface, drawing heat away from the processor instantly.

2. The Art of the Fin: Increasing Surface Area

The secret to effective passive cooling lies in the geometry of the exterior. To move heat from the metal into the air, you need surface area.

Integrated Cooling Fins: Through precision CNC machining or advanced extrusion, we can add a series of "fins" or "ribs" to the exterior of your enclosure.

Optimizing for Convection: At Coboggi, we help you calculate the optimal spacing and depth of these fins. If fins are too close, air gets trapped; if they are too far apart, you lose cooling efficiency.

3. The "Thermal Bridge": Connecting the PCB to the Shell

An aluminum enclosure is only effective if the heat can reach it. This requires a "Thermal Bridge."

Internal Standoffs: We machine internal "pedestals" that sit directly above hot components like the CPU or GPU.

TIM (Thermal Interface Material): By placing a thermal pad or grease between the component and the aluminum standoff, the heat "jumps" from the silicon to the metal shell with zero resistance.

The Result: Your internal components stay up to 30°C cooler than they would in a standard plastic box.

4. Aesthetics Meets Function

One common misconception is that cooling fins must look "industrial." At Coboggi, we prove otherwise.

Hidden Cooling: We can design internal fins or subtle textures that provide cooling benefits without ruining the sleek aesthetic of a smart home device.

Anodizing for Heat: Did you know that dark-colored anodized finishes (like matte black) actually have slightly better thermal emissivity? We help you choose the right finish that looks premium while working hard to keep the device cool.

Conclusion: Future-Proof Your IoT Hardware

Thermal throttling is the leading cause of "lag" in smart devices. By choosing an aluminum heat sink enclosure from Coboggi, you aren't just buying a box; you are investing in the long-term reliability and speed of your product.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish