As devices become smaller and more powerful—whether it’s a high-speed processor in a smart home hub, a high-torque motor in a personal care device, or a high-lumen LED in premium lighting—managing heat is critical.

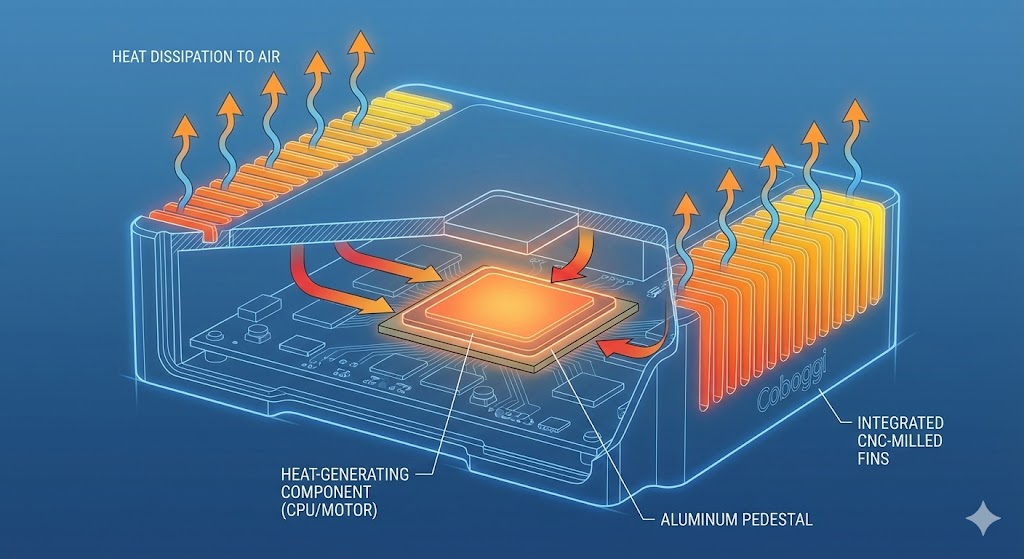

Thermal Sovereignty is the strategy of using the entire aluminum enclosure as a massive, passive heatsink.

At Coboggi, we don't just build "covers"; we engineer thermal management systems that allow your hardware to run faster, longer, and quieter.

1. Integrated Cooling Fins (Aesthetic Engineering)

Traditional heatsinks are ugly components hidden inside. With CNC machining, the heatsink becomes the design.

The Strategy: We mill deep, high-surface-area fins directly into the exterior of the aluminum chassis.

The Benefit: By integrating the cooling structure into the Visual Signature (#61), you eliminate the need for internal cooling components. This saves space, reduces weight, and creates a "technical" aesthetic that communicates power to the user.

2. Thermal Interface Optimization

For the enclosure to dissipate heat, the thermal path from the internal component to the metal wall must be perfect.

The Execution: We use ultra-high-tolerance milling to create "Thermal Pedestals." These are raised platforms inside the chassis that sit within microns of your heat-generating components (like a CPU or motor).

The Result: Combined with high-grade thermal pads, this creates a direct "heat bridge" to the outside world, effectively lowering internal temperatures by up to 30% compared to plastic-housed alternatives.

3. Maximizing Surface Area with Laser Processing

Heat dissipation is a game of surface area. The more metal touching the air, the faster the cooling.

The Tech: Beyond CNC-milled fins, we can use Laser Processing (#61) to create micro-textures or "porosity" patterns on the surface of the aluminum.

The Physics: These microscopic valleys increase the effective surface area of the enclosure without changing its physical footprint, boosting passive cooling efficiency.

4. The "Silent Performance" Advantage

Fans are the most common point of mechanical failure and the primary source of device noise.

The Marketing Edge: By achieving Thermal Sovereignty, your product operates in total silence. In Home Goods (like smart speakers) or Personal Care (like high-end clippers), silence is a premium feature.

Reliability: Removing a fan removes a moving part. This supports the Modular Advantage (#62) by ensuring the core shell can last for decades without a mechanical breakdown.

Conclusion: Power Without Compromise

Thermal management shouldn't be an afterthought—it should be a structural advantage.

By leveraging the natural conductivity of aluminum (approx. 205 W/m·K) and Coboggi’s precision engineering, your product can reach performance levels that plastic-housed competitors simply cannot match.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish