Carbon fiber is iconic, but it has limitations: it’s an insulator (traps heat), it can crack upon impact, and it’s difficult to recycle.

For many 3C and automotive brands, the goal is to capture the visual prestige of carbon fiber while retaining the mechanical advantages of aluminum—specifically its heat conductivity and structural "heft."

At Coboggi, we achieve this through high-speed 3D laser mapping and specialized anodizing.

1. The "Weave" Logic: 3D Laser Mapping

A real carbon fiber weave isn't just a print; it’s a series of overlapping ribbons that reflect light in different directions. To replicate this on aluminum, we don't just "etch" a pattern—we texture it.

Angular Micro-Vaneering: The laser carves microscopic "steps" at alternating angles (0° and 90°).

The Optical Result: When you rotate the part, the "fibers" seem to move and shimmer, exactly like a 3K twill weave. This is a 3D effect that traditional silk-screening or printing can never achieve.

2. Why Aluminum is the Superior Carrier

While carbon fiber looks great, using aluminum as the base material provides three critical benefits:

Thermal Management: In high-performance gaming laptops or chargers, the "carbon" surface actually acts as a massive heat sink.

EMI Shielding: Aluminum naturally blocks electromagnetic interference, protecting the sensitive electronics inside—something carbon fiber composites struggle with.

Precision Fit: We can machine complex screw threads and interlocking "no-gap" seams directly into the "carbon-textured" part, which is nearly impossible with molded carbon fiber.

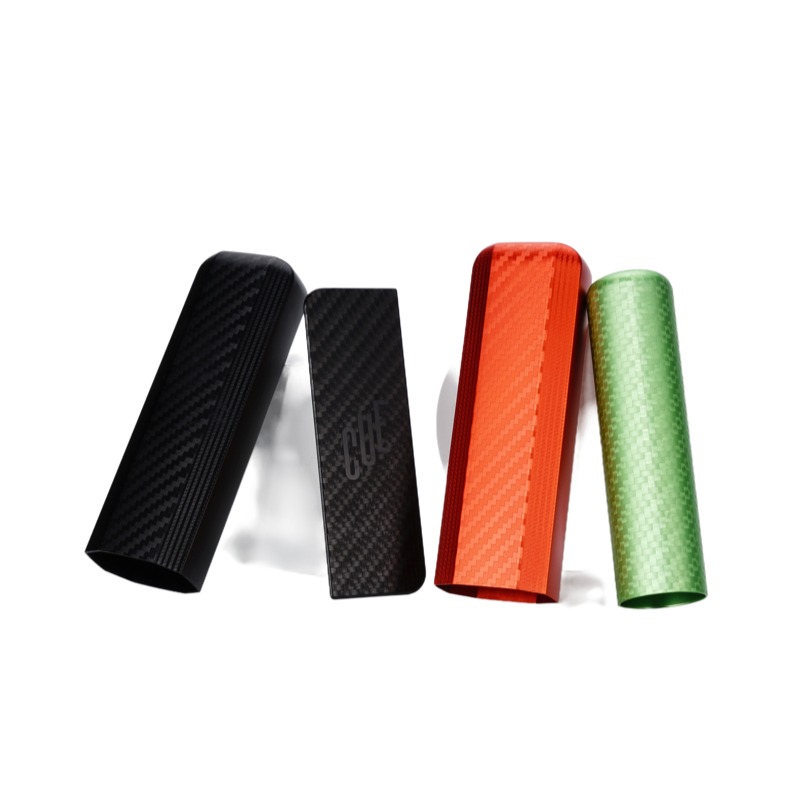

3. The Color Strategy: Beyond Black

Traditional carbon fiber is black. With Coboggi’s Anodizing, we can create "Exotic Carbon" looks that don't exist in nature:

Electric Blue Carbon: A deep blue anodizing over the weave texture.

Titanium Grey Carbon: A metallic, industrial look that feels like a military-grade alloy.

The "Depth" Seal: We use a high-gloss sealing process after anodizing to give the texture a "wet" look, mimicking the resin coating found on real high-end carbon fiber parts.

4. Tactile Feedback

Unlike a "skin" or a sticker, the texture is physically part of the metal.

The Hand-Feel: It feels slightly "woven" to the touch, providing a premium, non-slip grip that is perfect for handheld controllers, smartphone cases, or automotive gear shifters.

Durability: Because the pattern is engraved 20 μm to 50 μm deep into the metal, it will never peel, bubble, or wear away, even after years of friction.

5. Applications: Where Speed Meets Metal

Gaming Hardware: Mouse covers, laptop lids, and GPU backplates.

Automotive Interiors: Center console trims, paddle shifters, and door handle inserts.

Luxury Stationery: High-end pens that want to look "Aerospace" but feel "Metallic."

Conclusion: The Best of Both Worlds

Carbon Fiber Texture + Anodizing is the ultimate "cheat code" for designers. It allows you to wrap your product in the language of high-performance racing while maintaining the rock-solid reliability of CNC-machined aluminum.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish