Beyond the Spec Sheet: Why the surface treatment of your smart tech defines its longevity and luxury.

When we shop for smart home devices—whether it’s a sleek smart lock, a thermostat, or a high-end security camera—we often focus on battery life, connectivity, and megapixels. But there is a silent hero in hardware design that dictates how long your device lasts and how premium it feels in your hand: the finish.

At Coboggi, we understand that for aluminum-bodied devices, the manufacturing journey doesn't end at CNC machining. The surface treatment is what stands between the raw metal and the hazards of daily life.

Here is your guide to understanding aluminum finishes and choosing the right one for your next smart home project or purchase.

Why Aluminum in the First Place?

Before diving into finishes, it’s worth remembering why aluminum is the king of smart home materials. It is lightweight, possesses excellent strength-to-weight ratios, and, crucially for electronics, it acts as a natural heat sink. However, raw aluminum reacts with oxygen. While this natural oxide layer offers some protection, it isn't enough for a high-touch device. That is where professional finishing comes in.

The Top Contenders: Common Aluminum Finishes

Not all finishes are created equal. Here are the three most common processes used in the smart home industry, and what they bring to the table.

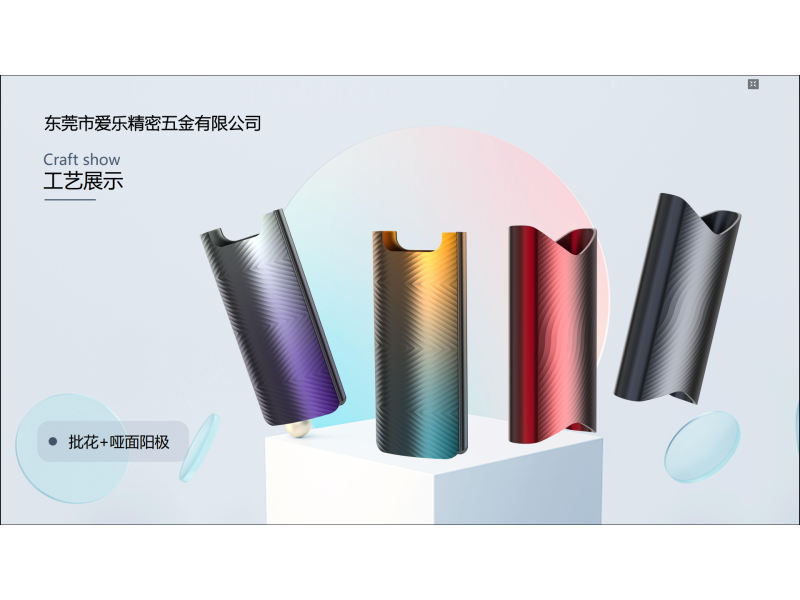

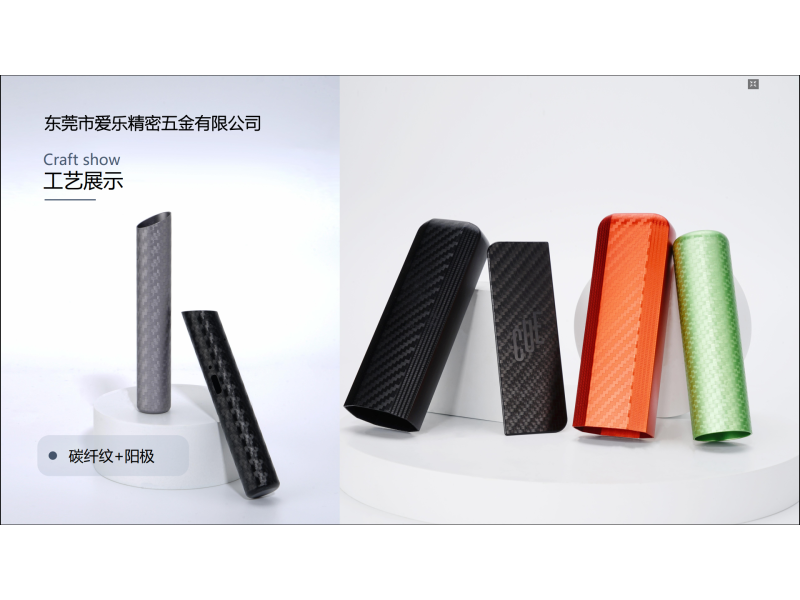

1. Anodizing: The Premium Standard

If you own a flagship smartphone or a high-end laptop, you are likely holding anodized aluminum.

The Process: This is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. It isn't a "coating" that sits on top; it is fully integrated with the underlying aluminum substrate.

Best For: Devices that are handled frequently (remote controls, smart knobs) and indoor aesthetics.

Pros: Incredible metallic look, resistant to peeling or chipping, and preserves the metal's natural texture.

Cons: Limited color palette compared to paint; difficult to achieve inconsistent matches across different batches.

2. Powder Coating: The Tough Shield

Powder coating involves spraying a dry powder onto the metal and then curing it under heat to form a "skin."

Shutterstock

The Process: It creates a thick, hard finish that is tougher than conventional paint.

Best For: Outdoor devices like smart doorbells, floodlights, or gate controllers that face rain, UV rays, and temperature swings.

Pros: extreme durability, huge variety of colors/textures (matte, gloss, rough), and eco-friendly (no solvents).

Cons: It can look "thicker" and less metallic than anodizing; it may mask the precise machining lines of the device.

3. PVD (Physical Vapor Deposition): The Jewelry Grade

PVD is often used for the high-gloss, gold, or stainless-steel looks found on luxury smartwatches and premium door hardware.

The Process: A vacuum coating process that produces a brilliant decorative and functional finish.

Best For: Accents, bezels, and luxury smart locks where scratch resistance and high-gloss aesthetics are required.

Pros: Extremely hard (high scratch resistance), hypoallergenic, and visually stunning.

Cons: Expensive to produce; usually reserved for smaller components rather than full device bodies.

Feature Anodizing Powder Coating PVD (Physical Vapor Deposition) Standard Liquid Paint Best For Premium indoor tech (phones, hubs) Outdoor devices (cameras, doorbells) High-end accents & luxury hardware Low-cost consumer electronics Durability High. Integrated into the metal; won't peel. Very High. Thick "skin" that resists impact. Extreme. Hardest surface; scratch-proof. Low/Medium. Prone to scratching/chipping. Heat Dissipation Excellent. Thin layer allows heat escape. Fair. Thick coating can trap heat. Good. Thin coating, but often on steel. Fair. Can act as an insulator. Aesthetics Metallic, natural texture. Uniform color, matte or textured. High gloss, jewelry-like (Gold/Chrome). Unlimited colors, but looks "plastic." Touch (Haptics) Cool, metallic feel. Smooth plastic-like or textured grit. Smooth, glassy, cold. Smooth or rubberized feel. Cost $$(Moderate) $$ (Moderate) $$$$ (Expensive) $ (Low)

Decision Framework: How to Choose?

When evaluating a smart device (or designing one), run it through this 3-point checklist to determine if the finish fits the function.

1. The Environment Test

Indoor: Anodizing is usually preferred for its sleek look and heat dissipation properties.

Outdoor: Powder coating or specialized outdoor-grade anodizing is non-negotiable. If you put a standard anodized device in direct coastal salt air, it may pit over time.

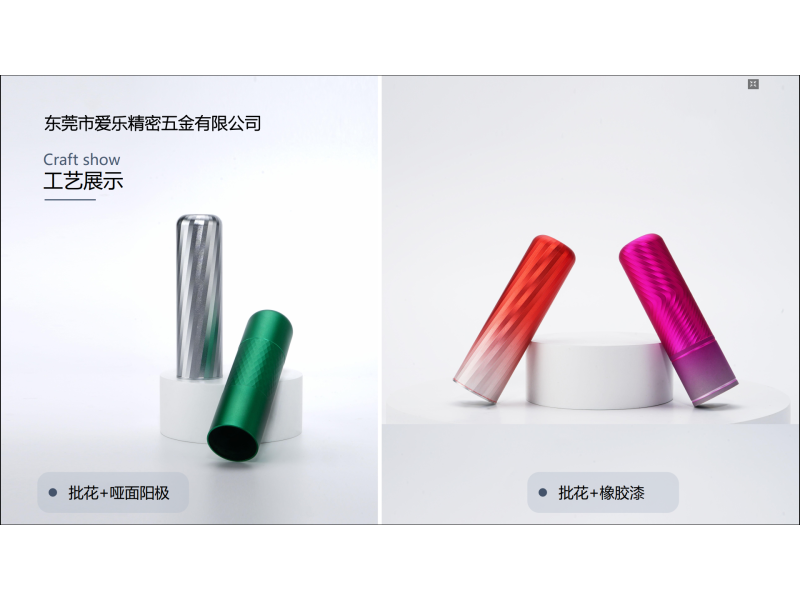

2. The "Hand-Feel" (Haptics)

Smart home devices are tactile. We touch thermostats, keypads, and scanners.

Matte Finishes (Bead Blasted + Anodized): Hide fingerprints and oils best.

Glossy/Polished: Look premium out of the box but require constant cleaning to look good.

3. Thermal Management

Smart devices get hot. Thick layers of paint or powder coating can act as insulators, trapping heat inside. Anodizing is superior for heat dissipation because the oxide layer is very thin, allowing the aluminum body to effectively pull heat away from the processor.

The Coboggi Verdict

Durability is not just about surviving a drop; it’s about surviving time. A smart device should look as good two years later as it did on day one.

Choose Anodizing if you want that "Apple-esque" premium feel and the device lives indoors.

Choose Powder Coating if the device needs to survive a storm or rough handling.

At Coboggi, we prioritize finishes that balance these needs—ensuring that the beauty of the device matches the intelligence of the software inside.

What’s your preference for smart home aesthetics: the raw metallic look or a matte color finish? Let us know in the comments!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish