In the hardware world, Inventory is Debt. Every finished chassis sitting on a shelf represents "trapped capital" that isn't earning interest, isn't being marketed, and is at risk of becoming obsolete.

At Coboggi, we’ve moved beyond 20th-century "Mass Production" and into Lean Scaling.

We use 2025 AI-integration to align our CNC spindles with your actual sales data, ensuring your growth is fueled by profit, not just volume.

1. AI-Driven Demand Forecasting

Traditional manufacturing relies on "guesses" (Purchase Orders) made months in advance.

The Coboggi Shift: We integrate with our partners' supply chain data to monitor real-time sell-through rates.

The Benefit: If a specific color (like "Midnight Blue") is selling faster than "Space Gray," we can pivot our automated anodizing lines in 48 hours to meet the trend.

The Result: You never have a stockout on your bestsellers, and you never have "Dead Stock" on your slow-movers.

2. Reducing "Physical" Waste: The Green ROI

Waste isn't just bad for the planet; it’s a hole in your balance sheet.

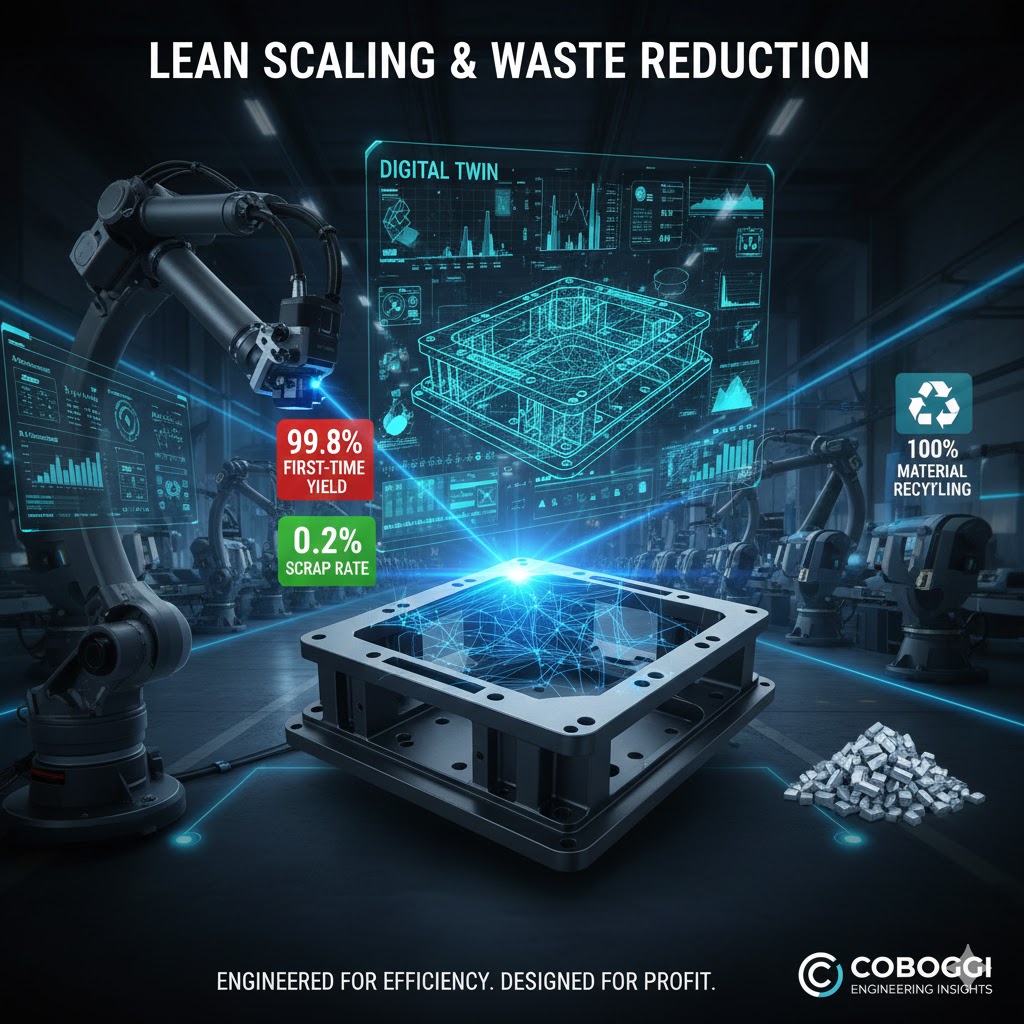

Precision Nesting: We use AI software to "nest" parts within an aluminum billet to maximize yield.

Chip Recycling: 100% of our aluminum "swarf" (the shavings from CNC milling) is vacuum-collected, compressed into briquettes, and sent back for re-smelting.

Financial Impact: High material utilization means lower "Raw Material Surcharge" for you.

3. The "Batch of One" Capability

The old way of scaling required massive "Minimum Order Quantities" (MOQs).

The Strategy: By using Quick-Change Tooling and robotic cells, Coboggi reduces "Set-up Time" to near zero.

The Outcome: We can run smaller, frequent batches that mirror your weekly sales. This keeps your cash flow "liquid" rather than frozen in a warehouse.

4. Error Waste: "First-Time-Through" Yield

Waste also comes in the form of rejected parts.

The Tech: We employ Automated Optical Inspection (AOI). Every part is scanned by a high-resolution camera system that detects surface defects invisible to the human eye.

The ROI: Our "First-Time-Through" yield is 99.8%. You stop paying for the 5-10% "scrap rate" that is common in lower-tier factories.

Conclusion: Efficiency is the Ultimate Scale

Scaling isn't about being the biggest; it's about being the most efficient. Lean Scaling allows a hardware brand to act like a software company—agile, data-driven, and highly profitable. With Coboggi, you don't just grow your footprint; you grow your margins.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish