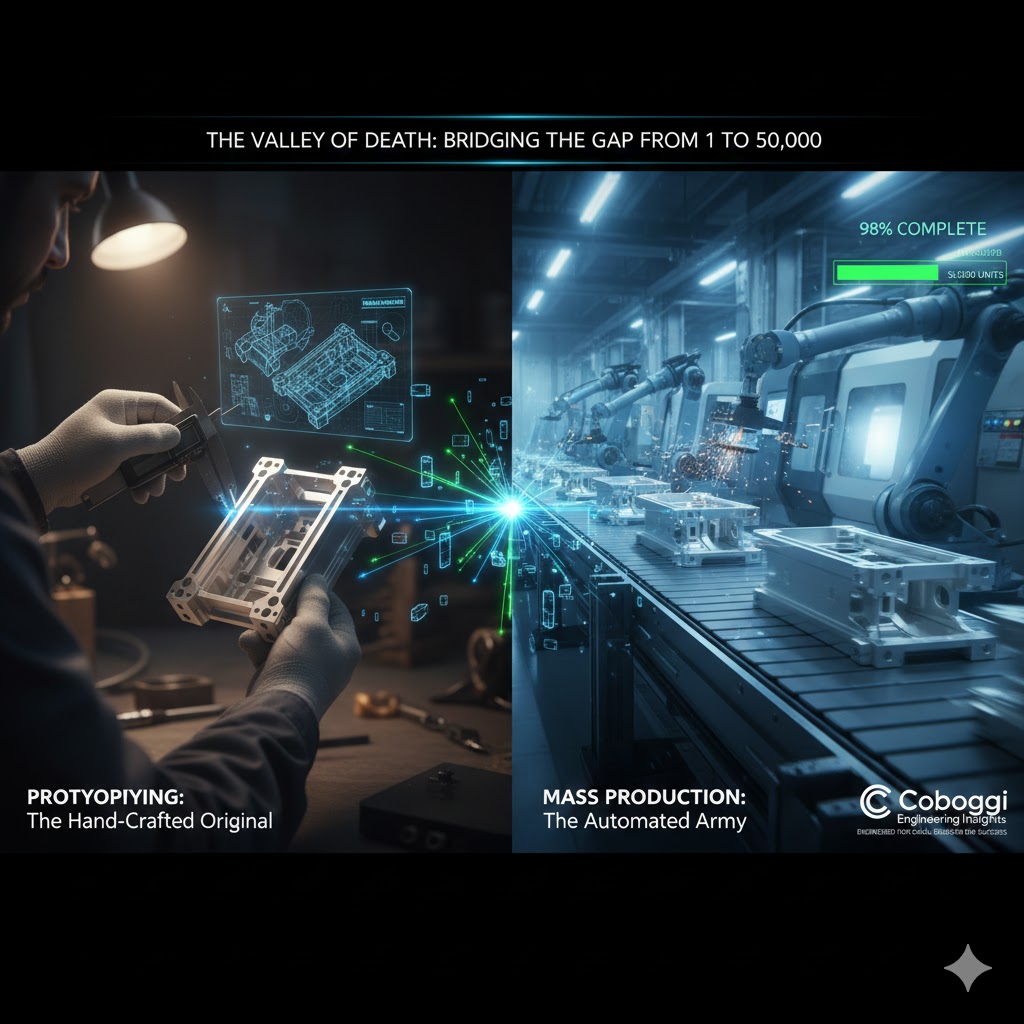

The world is full of "Great Ideas" that never made it to market.

Why? Because a prototype that looks good on a desk is very different from a product that can be manufactured 50,000 times with zero defects.

At Coboggi, we specialize in The Bridge Strategy. We don't just "take your file and print it"; we engineer a pathway from your vision to global distribution.

1. DFM (Design for Manufacturing): The Reality Check

Prototyping often uses "expensive" workarounds—slow CNC paths or hand-finishing—that are impossible at scale.

The Coboggi Audit: Before we hit "Go" on Batch #3, we perform a DFM audit. Can we change a 90-degree internal corner to a 3mm radius to speed up machining by 30%? Can we simplify the jigging process?

The ROI: Small design tweaks at the prototype stage can save $5.00 per unit in mass production. On 50,000 units, that’s $250,000 in saved profit.

2. The EVT / DVT / PVT Framework

We guide you through the industry-standard "Testing" gates to ensure your product is bulletproof.

EVT (Engineering Validation): Does the aluminum chassis fit the electronics?

DVT (Design Validation): Does the finish survive salt-spray tests and drop tests?

PVT (Production Validation): This is the "Pilot Run." We run 100-500 units on the actual mass production line to find the "bugs" before the big launch.

3. Tooling Hardening and Fixture Strategy

A prototype uses "soft" temporary fixtures. Mass production requires "hard" automated jigs.

The Bridge: Coboggi develops High-Repeatability Fixtures during the PVT phase. These are designed for our robotic arms to load and unload with sub-micron precision.

Consistency: This transition ensures that the "soul" of your prototype isn't lost when the machines start running 24/7.

4. Scaling the Supply Chain (The "BOM" Lockdown)

As you move to mass production, your Bill of Materials (BOM) must be locked.

The Strategy: We help you source raw aluminum in bulk early to "lock in" the price and grade. This prevents the "Material Drift" where unit #1,000 uses a different alloy quality than unit #40,000.

The Result: Your margins stay predictable even as your volume explodes.

Conclusion: Stop Guessing, Start Scaling

The "Valley of Death" is littered with hardware companies that tried to skip steps.

At Coboggi, we provide the map and the vehicle to get you across. We make the transition from "One" to "Many" a calculated, repeatable process rather than a gamble.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish