In the "spec-sheet wars" of 2025, performance is everything.

But performance generates heat. If your device gets too hot, the processor slows down to protect itself—this is Thermal Throttling, and to your customer, it feels like they bought a broken product.

Many brands try to solve this with noisy fans or expensive liquid cooling. At Coboggi, we advocate for Passive Thermal Strategy: using the aluminum chassis itself as a functional component of the cooling system.

1. The "Chassis-as-a-Heatsink" Strategy

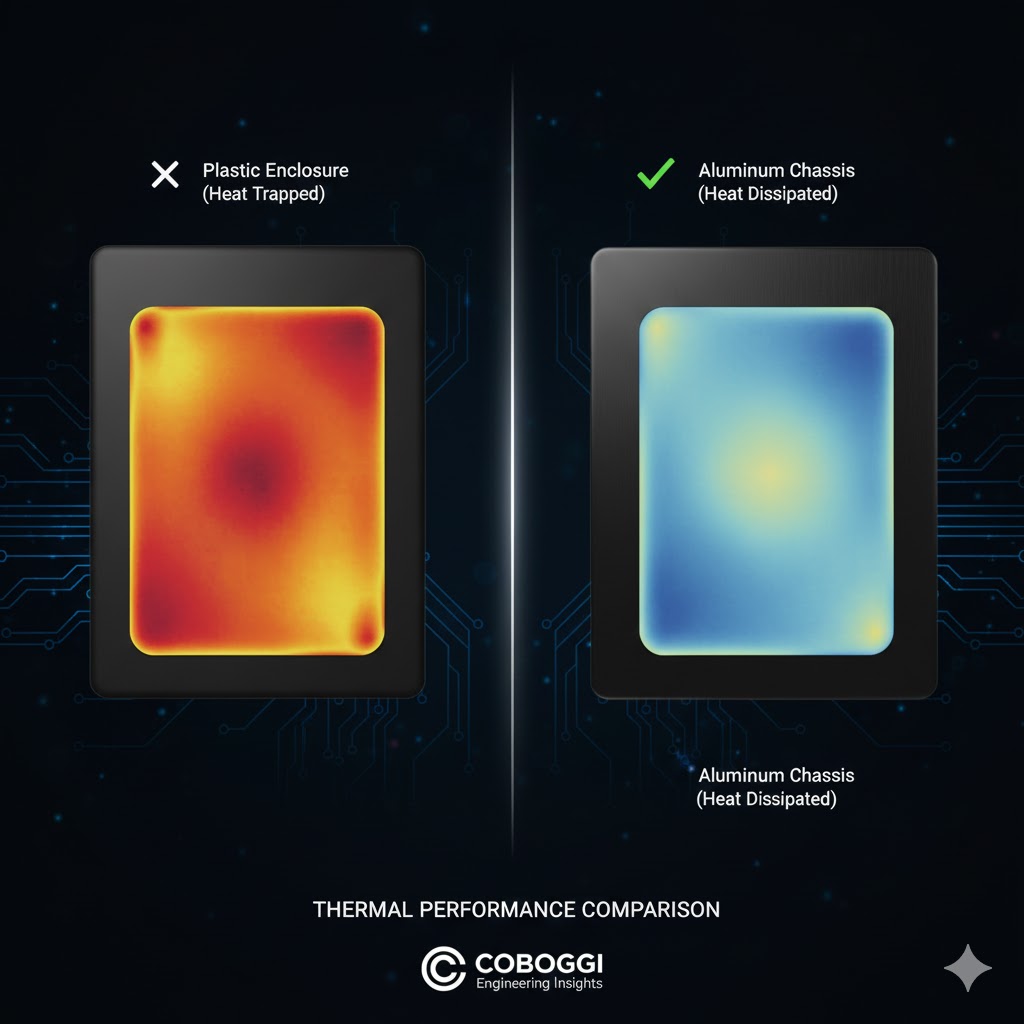

Standard plastic enclosures act as insulators; they trap heat inside, cooking the delicate capacitors and chips.

The Difference: Aluminum has a thermal conductivity of ~205 W/m⋅K,—nearly 1,000x higher than most plastics.

The ROI: By engineering the internal components to touch the aluminum outer shell (using thermal pads), the entire surface area of the device becomes a heat radiator.

The Business Logic: You eliminate the cost of internal fans, reduce the device's thickness, and remove a mechanical "point of failure" (the fan motor).

2. Protecting Battery Health (The Replacement Cost)

Heat is the 1st enemy of Lithium-Ion batteries. A battery that consistently operates at 45℃ will lose its capacity twice as fast as one at 25℃.

The Risk: A "hot" device leads to "Battery Bloat" and premature failure, forcing the customer to demand a replacement or leave a 1-star review.

The Necessary Investment: Using aluminum for the battery cradle allows the metal to pull heat away from the cells during rapid charging.

The Value: You extend the "Usable Life" of the device by 30-50%. This creates a reputation for "Indestructible Hardware" that allows you to maintain high resale value.

3. Why "Radiant" Finishing Matters

Not all aluminum finishes are equal when it comes to heat.

The Science: Anodizing increases the Emissivity of the aluminum surface. A black anodized finish radiates heat significantly better than a raw or polished surface.

The Benefit: We can tune the finish (pore depth and color) to optimize how the device sheds heat in stagnant air.

The ROI: This small adjustment in the finishing process can lower internal temperatures by 3-5℃—often the exact margin needed to prevent a system crash.

4. The Economic Impact of "Safe" Temperatures

Warranty Savings: Lower operating temperatures mean a lower "Failure Rate Over Time" (the Bathtub Curve). If your failure rate drops from 2% to 0.5%, that is pure profit straight to your bottom line.

Regulatory Speed: Devices that stay cool are easier to certify for safety standards (like UL or CE), getting you to market faster and with lower legal risk.

Conclusion: Heat is a Liability. Aluminum is the Hedge.

Thermal management shouldn't be an afterthought. It is a fundamental part of your Business Risk Management.

By investing in a precision-engineered aluminum thermal path, you are choosing a silent, reliable, and highly efficient cooling system that protects your components, your customers, and your margins.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish