In the "New Energy" era, efficiency is the only metric that matters. For an e-bike, less weight means more range.

For a drone, less weight means more payload. For an EV charger, better heat dissipation means faster charging.

Aluminum is the foundational material for this transition. It is one-third the density of steel, naturally corrosion-resistant, and—critically for the green energy narrative—it can be recycled infinitely without losing its properties.

At Coboggi, we provide the precision-engineered components that keep the world moving.

1. High-End E-Bikes: Beyond the Tube

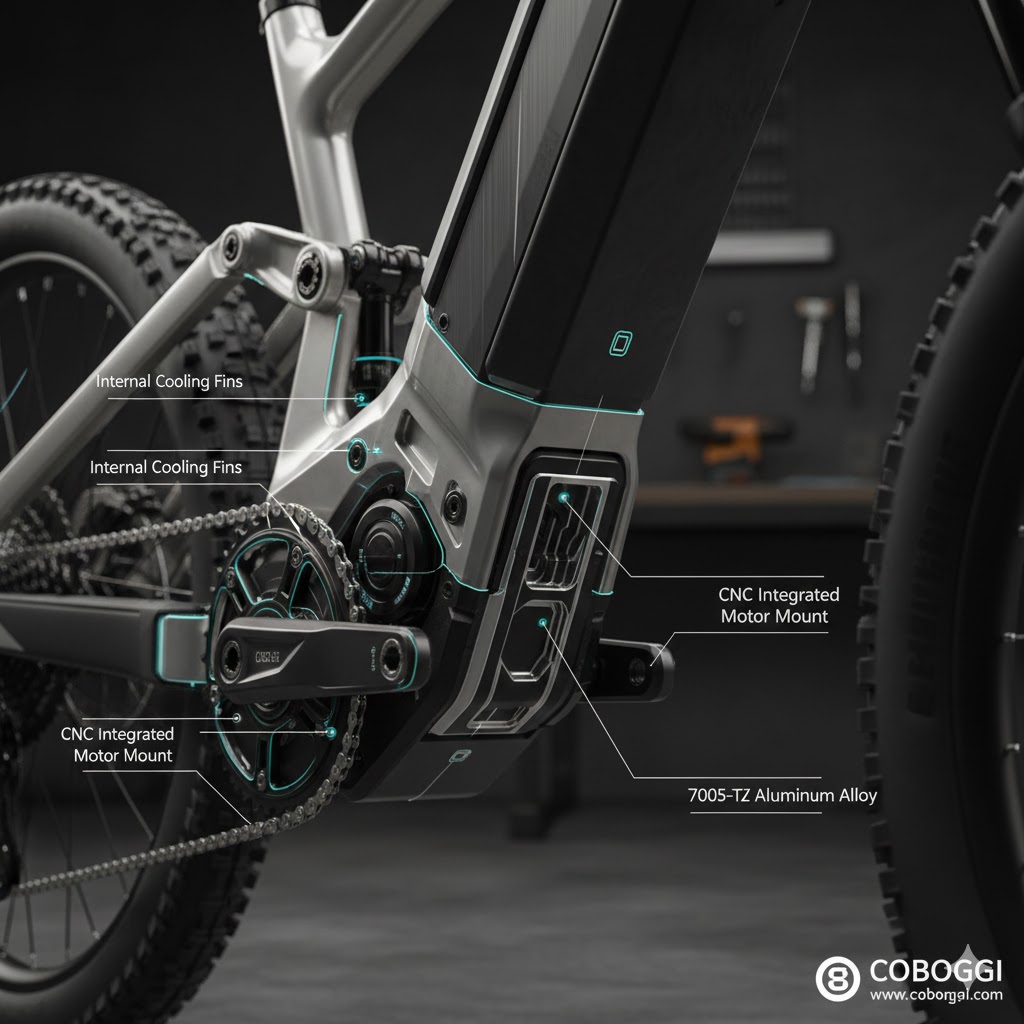

Modern e-bikes are no longer just bicycles with motors; they are integrated "Smart Vehicles."

Hydroformed & CNC-Integrated Frames: We use a combination of hydroforming for the main tubes and 5-axis CNC machining for the motor mounts and battery cradles. This ensures the motor is perfectly aligned, reducing wear on the chain and gears.

Fatigue-Resistant Alloys (6061-T6 / 7005): We certify every batch of aluminum for fatigue resistance, ensuring that frames can withstand the high torque of mid-drive motors and the vibrations of urban commuting for decades.

2. The Drone Revolution: Stiffness vs. Grams

For commercial delivery and inspection drones, the frame is a high-performance skeletal system.

Monolithic Motor Mounts: We CNC-mill motor mounts from single blocks of 7075-T6 aluminum. This "Monolithic" design eliminates the vibrations that can interfere with flight controllers and camera gimbals.

Ultra-Thin Wall Profiles: By utilizing high-precision milling, we can achieve wall thicknesses that are thin enough to save weight but structurally reinforced in high-stress zones to prevent snapping during hard landings.

3. EV Infrastructure: The "Front Line" of the Grid

EV charging poles are high-voltage electronic enclosures that live outdoors in rain, snow, and salt air.

Extruded Thermal Management: The "guts" of a DC fast charger generate massive heat. We design the outer aluminum shell with integrated cooling fins (extrusions) that pull heat away from the power modules without needing energy-intensive fans.

Marine-Grade Protection: For coastal charging stations, we apply specialized anti-corrosion seals to our anodized finishes, ensuring the "brand image" of the charging network stays pristine for years.

4. Sustainable Supply Chains (The "Green" Metal)

New Energy brands are often judged by their carbon footprint.

Recycled Content Integration: Coboggi works with suppliers to source low-carbon aluminum and recycled scrap, helping our clients meet the strict sustainability targets required by European and North American markets.

Circular Design: We design components for easy disassembly, ensuring that at the end of a vehicle's life, the aluminum parts can be stripped and melted back into new components.

5. Applications: Powering the Future

Electric Vertical Take-off (eVTOL): Large-scale aluminum structural nodes that hold rotors and battery packs.

Portable Power Stations: Rugged, heat-dissipating aluminum cases for "off-grid" energy storage.

Micro-Delivery Robots: Lightweight chassis that allow for maximum battery life in "last-mile" delivery scenarios.

Conclusion: Efficiency Through Material Intelligence

The New Energy economy is built on the pursuit of "More from Less." More range from less weight. More power from less heat. At Coboggi, we provide the material intelligence and manufacturing precision to make that efficiency possible.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish