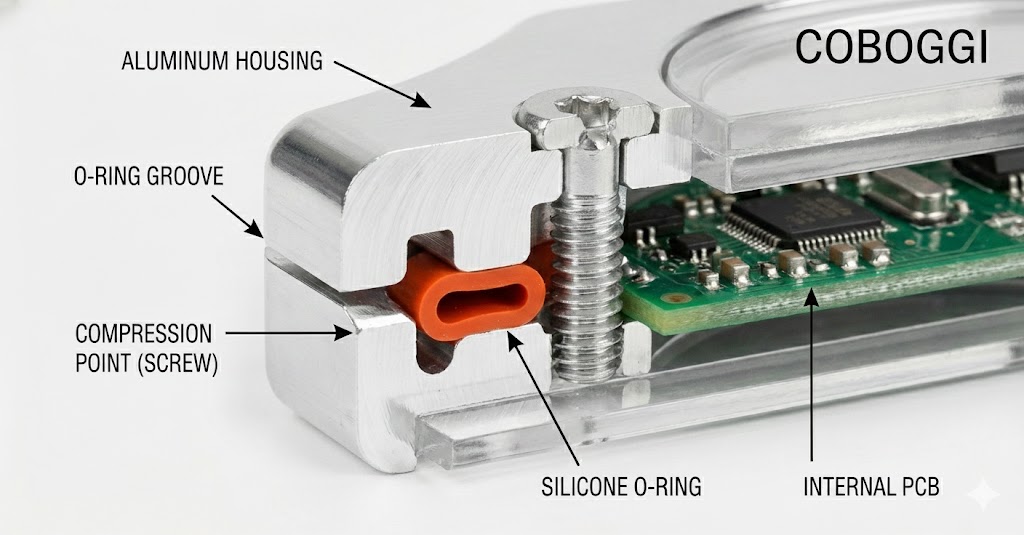

In the world of Personal Care, a device that cannot survive a drop in the sink—or a session in the shower—is a failure. Achieving an IPX7 rating (immersion in 1 meter of water for 30 minutes) in a CNC aluminum body requires more than just a tight fit; it requires "Seal Geometry."

At Coboggi, we engineer waterproofing into the very skeleton of the device, ensuring the internal electronics remain bone-dry without sacrificing the Visual Signature (#61).

1. The Precision O-Ring Groove

The most effective way to seal an aluminum product is the O-ring. However, the performance of the seal depends entirely on the precision of the groove it sits in.

The Engineering: We machine grooves with tolerances of ±0.01mm.

The Compression: We calculate the "Gland Fill"—ensuring the O-ring has enough space to expand under pressure but is compressed by exactly 20–25% to create a watertight barrier.

The Benefit: This allows for a completely tool-less, "screw-on" waterproof assembly for Personal Care jars or battery compartments.

2. Surface Finish vs. Capillary Action

A common mistake in waterproofing is leaving the machined surface too rough. Microscopic "peaks and valleys" in the metal can create channels for water to seep through (capillary action).

The Coboggi Edge: We ensure that any surface touching a seal is polished to a high Ra (Roughness Average).

The Result: A smooth, mirror-like "seal-seat" that prevents even the smallest water molecules from bypassing the gasket.

3. Sealing the "Invisibles": Ports & Buttons

The biggest vulnerabilities in Electronics are the charging ports and the buttons.

The Strategy: For charging, we move toward Magnetic Pogo-Pins that are flush-mounted and sealed with industrial-grade epoxy from the inside.

For Buttons: We utilize "Internal Plunger" systems where a flexible silicone membrane is trapped behind a CNC aluminum button cap. This gives the user the cold touch of metal while the silicone does the invisible work of blocking water.

4. Pressure Equilibrium (The Gore-Tex Approach)

Air expands and contracts with heat. If a device is perfectly sealed, a change in temperature can create a vacuum that actually "sucks" water past the seals.

The Execution: In some Home Goods or outdoor electronics, we machine a tiny internal "vent" covered with a hydrophobic membrane.

The Impact: It allows the device to "breathe" (release air pressure) while remaining 100% waterproof.

Conclusion: Built for the Real World

Waterproofing shouldn't feel like an add-on; it should feel like an inherent part of the product's durability. By mastering the intersection of seal physics and CNC precision, Coboggi ensures your hardware isn't just beautiful—it's indestructible in the face of the elements.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish