At Coboggi, we believe that the soul of an enclosure lies in its finish.

An aluminum alloy housing is more than just a protective shell; it is a tactile experience where precision engineering meets artistic expression. To achieve the perfect balance of durability and aesthetic brilliance, we employ an elite suite of CNC machining and electrochemical processes.

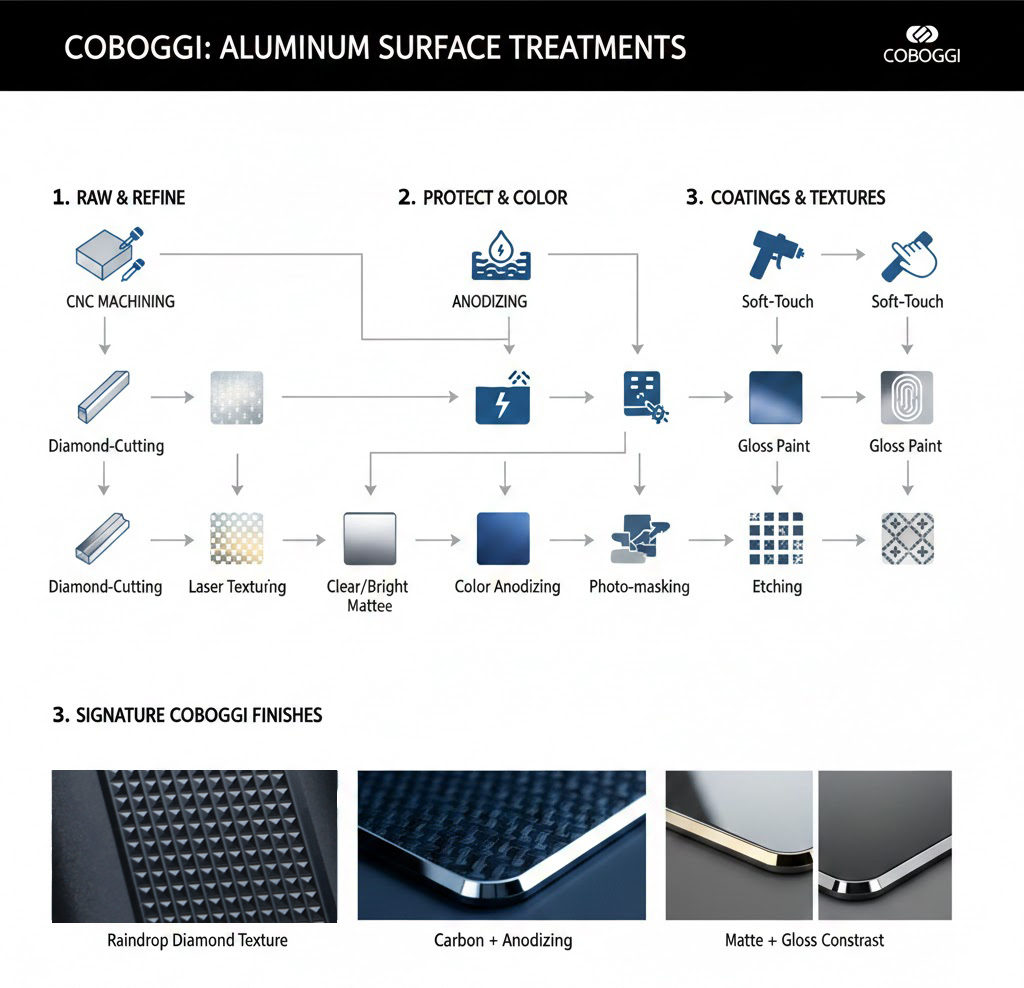

Here is an in-depth look at the advanced surface treatment technologies that define our manufacturing core.

1. The Foundation: CNC Machining & Anodizing

Every Coboggi enclosure begins with high-precision CNC Machining. We mill solid aluminum blocks to micron-level tolerances. To protect this precision, we apply Anodizing, an electrochemical process that converts the metal surface into a hard, decorative, and corrosion-resistant anodic oxide finish.

For projects requiring a vibrant brand identity, our Color Anodizing process offers a spectrum of deep, metallic hues—from Space Gray to Emerald Green—ensuring the color is chemically bonded to the metal for a lifetime of use.

2. High-Reflectivity Techniques: Diamond-Cutting & Bright Finishes

To create visual highlights that capture the light, we utilize Diamond-Cutting . Using natural diamond tools, we shave the aluminum to create a mirror-like shine.

Bright Anodizing: Combined with diamond-cutting, this creates a high-gloss, premium metallic luster.

Raindrop Diamond Texture : A signature Coboggi finish where the CNC creates thousands of microscopic, teardrop-shaped facets, resulting in a sparkling "raindrop" shimmer across the surface.

3. Sophisticated Texturing: Hidden Patterns & Carbon Effects

For a more subtle, high-end aesthetic, we offer "Ghost" textures:

CNC CD Texture : These are microscopic concentric grooves that create a sunburst light-shifting effect, commonly used on camera rings and volume knobs.

Carbon Fiber Texture : Through specialized laser texturing or 3D milling, we replicate the iconic weave of carbon fiber directly onto the aluminum, finished with a protective anodized layer.

4. Advanced Patterning: Photo-Masking & Etching

When designs require intricate logos or complex graphics, we move beyond simple engraving:

Photo-masking : Utilizing UV-exposure and development, we can apply high-definition patterns with photographic precision.

Chemical Etching: This process allows for deep, textural contrasts by selectively removing metal layers before the final anodizing stage, creating a sophisticated "tone-on-tone" effect.

5. Tactile Contrast: The Hybrid Finish

Modern product design often requires a mix of "Hard" and "Soft" sensations. We achieve this by combining mechanical cutting with high-performance coatings:

Matte Anodizing + Diamond-Cut: A non-reflective, sandblasted body paired with razor-sharp, shiny silver edges.

Soft-Touch Coating : We apply a specialized velvet-feel resin over the aluminum. When paired with Diamond-Cutting, the result is a product that is grippy and warm to the touch, yet accented by cold, brilliant metallic highlights.

The Coboggi Quality Standard

Quality at Coboggi is measured in microns and Delta-E values. We ensure:

Uniformity: Strict control over Color Anodizing to ensure zero batch-to-batch variation.

Durability: All coatings, including Gloss Painting and Soft-Touch finishes, undergo rigorous cross-hatch adhesion and salt-spray testing.

Precision: Every Laser Texture and Diamond-Cut edge is inspected under magnification for absolute clarity.

Coboggi: Redefining the Surface of Innovation.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish