In high-end Consumer Electronics and Personal Care devices, status lights and indicators must be crisp.

There is nothing that cheapens a premium aluminum device faster than "blurry" light or glow leaking out from the seams of the USB port.

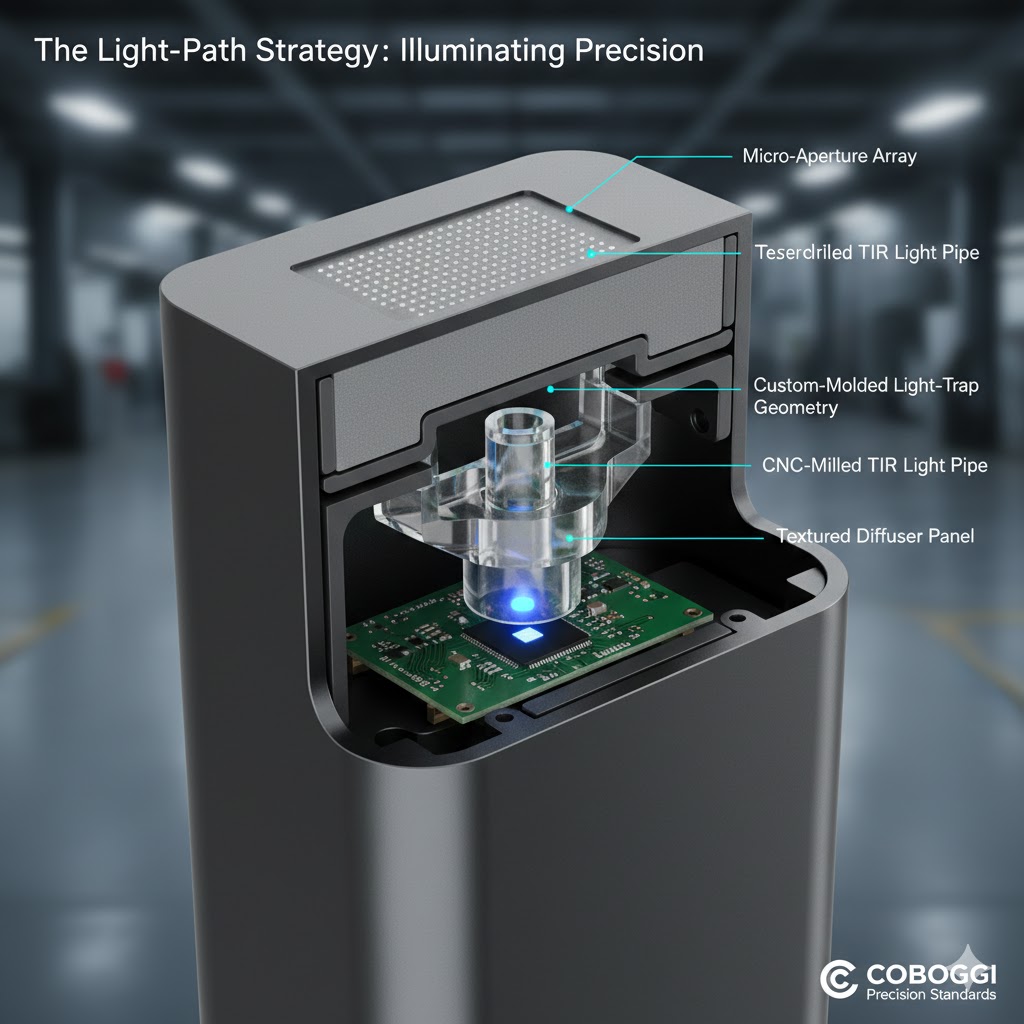

The Light-Path Strategy is about controlling every photon from the PCB to the user’s eye, using the aluminum enclosure as a structural "light-gate."

1. Micro-Aperture Drilling (The "Hidden-Until-Lit" Effect)

One of the most sophisticated ways to show status is to make the light appear as if it is shining directly through the metal.

The Tech: Using specialized CNC or laser drilling, we create a grid of microscopic holes (often 0.1mm or smaller) that are invisible to the naked eye when the LED is off.

The Result: When the device wakes up, the light shines through the "solid" aluminum. This maintains the Zero-Tolerance Fit (#65) aesthetic while providing clear functional feedback.

2. Total Internal Reflection (TIR) Light Pipes

To move light from a deep-set PCB to the surface without losing brightness or clarity, we use custom-molded or machined "Light Pipes."

The Engineering: These clear acrylic or polycarbonate components are designed to snap into the aluminum housing with a Zero-Tolerance Fit.

Light Leak Prevention: We often "mask" the edges of these pipes or create a secondary "gasket" within the CNC pocket of the aluminum to ensure that light only exits where intended.

3. The "Light-Trap" Geometry

Aluminum’s reflective nature can actually work against you, causing internal "bounce" that makes one LED bleed into the neighbor’s indicator.

The Strategy: We mill specific "isolation chambers" or "baffles" directly into the internal side of the aluminum chassis.

The Benefit: Each LED sits in its own CNC-milled "room," ensuring that your "Battery Low" light doesn't accidentally illuminate your "Bluetooth Pairing" icon.

4. Material Harmony: Aluminum & Diffusion

The quality of light is just as important as the direction.

The Execution: We pair precision aluminum cutouts with frosted or bead-blasted diffusers.

The Haptic Connection: By matching the texture of the light diffuser to the Anodizing Standard (#61) of the metal, the transition between light and metal feels intentional and seamless.

Conclusion: Control the Glow

Light should be a scalpel, not a floodlight. By mastering the interaction between photons and precision-milled aluminum, Coboggi ensures that your product’s interface is as sharp and professional as its physical structure.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish