In the world of mass-market plastic, "gaps" and "creaks" are expected. In the world of Coboggi aluminum, they are unacceptable.

Zero-Tolerance Fit is the engineering discipline of ensuring that every point of contact—where two parts meet, where a button sits in its housing, or where a lid slides onto a base—feels like it was carved from a single, solid block.

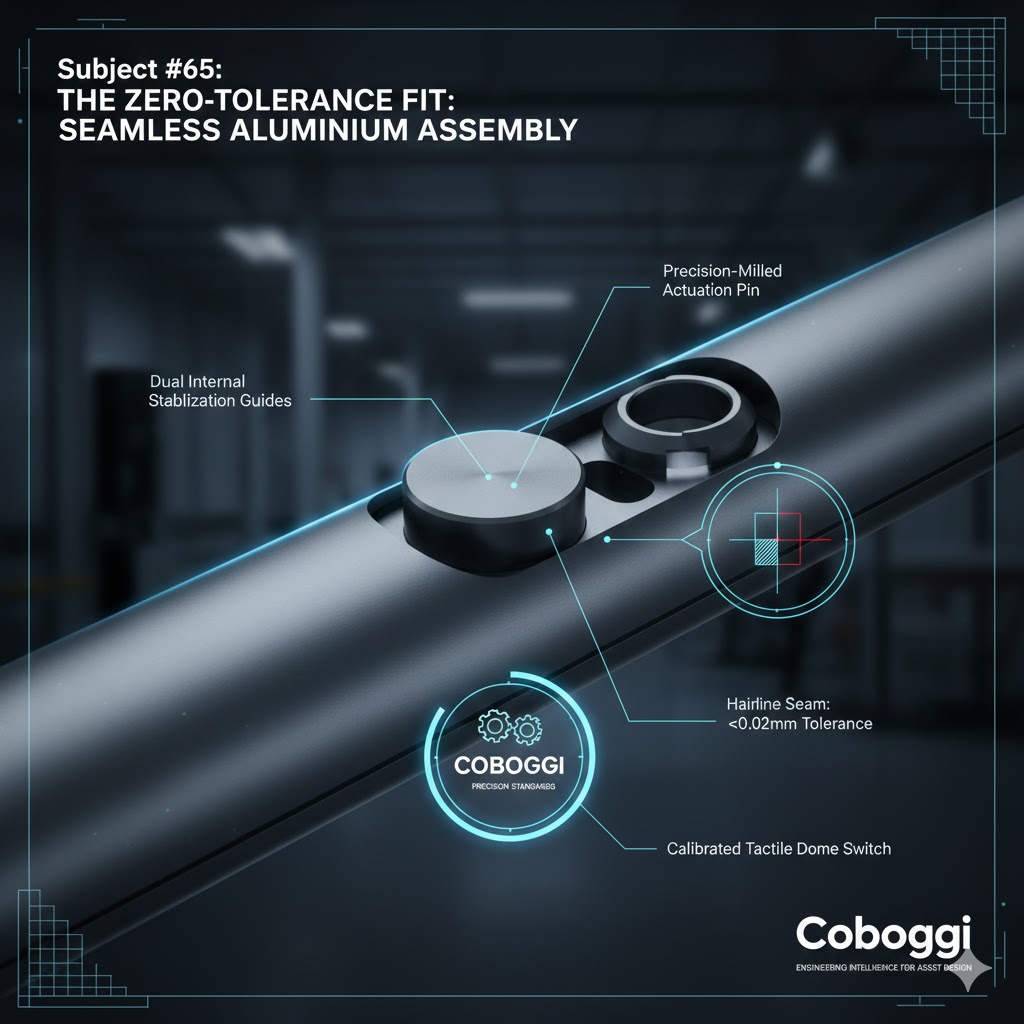

1. The Invisible Seam (Hairline Precision)

When two machined aluminum parts join together, the "parting line" should be felt by a fingernail but nearly invisible to the eye.

The Strategy: We utilize Match-Machining, where the two mating components are finished using the same toolpath logic to ensure the grain and the edges align perfectly.

The Benefit: This eliminates "stair-stepping" between parts, common in lower-quality manufacturing. It creates a monolithic look that is a hallmark of luxury Consumer Electronics and Personal Care devices.

2. The "Vacuum-Seal" Experience

There is a specific, high-end sensation when a lid or battery cover slides into place and the air is slowly displaced.

The Engineering: By maintaining tolerances within ±0.01mm, we create a piston-like fit.

The Result: The part doesn't "drop" or "wiggle"; it glides. This "dampened" movement provides a premium user experience every time a customer interacts with the product’s internal modules, reinforcing the Modular Advantage (#62).

3. Kinetic Tactility: Button & Switch Engineering

The most frequent point of contact between a user and your brand is a button.

The Problem: Most buttons have "rattle" or side-to-side play because the hole in the enclosure is too large.

The Coboggi Solution: We use precision-milled guides and internal stabilizers so that an aluminum button has zero lateral movement.

The Click: We calibrate the "actuation force" so that the mechanical click is crisp and consistent across all units, ensuring your Personal Care or Home Goods product feels like a high-precision tool.

4. Structural Integrity & Shielding

A zero-tolerance fit isn't just an aesthetic choice; it’s a functional necessity for high-performance hardware.

EMI Shielding: Tighter seams mean better protection against electromagnetic interference, crucial for sensitive Consumer Electronics.

Dust and Water Resistance: While gaskets do the heavy lifting, a precision-milled mechanical fit provides the first line of defense, making the final sealing process much more effective.

Conclusion: Perfection in the Details

Zero-tolerance engineering is where the "soul" of the product lives. It tells the user that every millimeter was considered, debated, and perfected.

At Coboggi, we provide the sub-micron precision required to turn a collection of parts into a single, cohesive masterpiece.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish