In our hyper-connected world, the air is thick with "electronic noise." Wi-Fi signals, Bluetooth, cellular data, and even the internal components of a device all emit electromagnetic waves. When these waves interfere with a device's sensitive internal circuitry, it results in Electromagnetic Interference (EMI).

For a consumer, EMI means dropped calls, "buzzing" in audio equipment, or slow data speeds. For a manufacturer, it means failing regulatory certifications (like FCC or CE). At Coboggi, we solve this problem at the source: the enclosure.

1. The Science: The Faraday Cage Effect

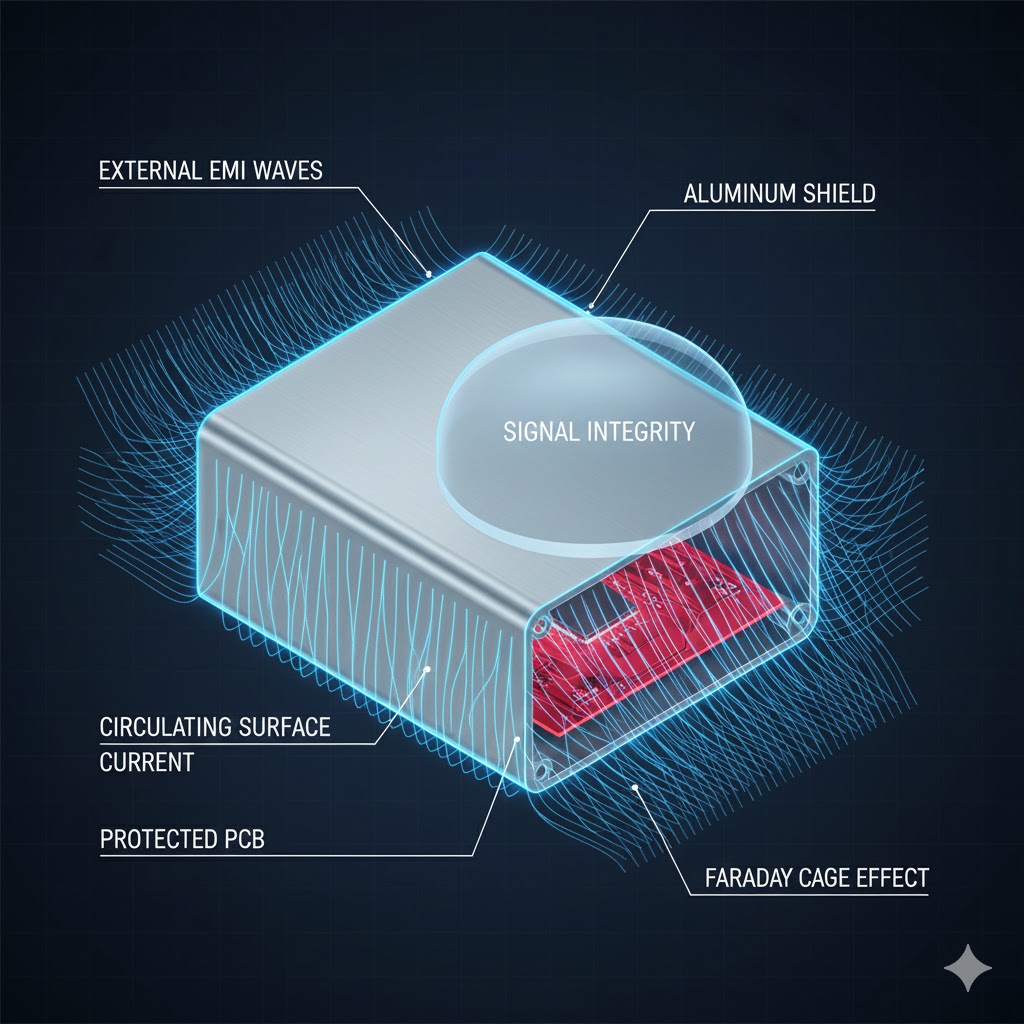

When you house electronics in a solid Aluminum 6061 enclosure, you are essentially creating a Faraday Cage.

A Faraday cage is a grounded metal screen or solid shell that surrounds a piece of equipment. Because aluminum is a highly conductive metal, it absorbs incoming electromagnetic waves and distributes the charge around the exterior of the shell, preventing the interference from ever reaching the PCB (Printed Circuit Board) inside.

2. Why Aluminum 6061?

While many metals can provide shielding, Aluminum 6061 is the "goldilocks" material for 3C electronics:

High Conductivity: It effectively conducts and dissipates RF (Radio Frequency) energy.

Lightweight: Unlike steel or copper, it provides high-level shielding without making a handheld device feel like a brick.

CNC Machinability: We can machine internal "walls" directly into the chassis to isolate different parts of the circuit (e.g., separating the power supply from the sensitive antenna module).

3. The "Seam Problem": Precision is Everything

An EMI shield is only as strong as its weakest point. In the world of RF, a tiny gap in a housing is like a hole in a bucket.

The Leak: If the lid of an enclosure doesn't fit perfectly with the base, electromagnetic waves can "leak" through the seam.

The Coboggi Solution: This is where our ±0.01mm tolerances become a functional necessity. By ensuring the mating surfaces of the enclosure are perfectly flat and tight, we maximize "electrical continuity" across the entire surface, sealing the device against interference.

4. Finishing Considerations: Anodizing vs. Conductivity

Here is a technical tip from our engineering lab: Anodizing is an insulator. While anodized finishes look beautiful, they can actually block the electrical contact needed for a perfect Faraday cage. At Coboggi, we use specialized techniques to solve this:

Selective Masking: We mask off specific internal contact points or screw holes before anodizing to ensure metal-to-metal contact for grounding.

Conductive Gaskets: We design grooves for EMI gaskets that bridge the gap between two aluminum parts, ensuring a 360-degree shield.

Conclusion: Built-In Signal Security

As we move into the era of 5G and ultra-fast IoT, signal integrity is no longer "optional." By choosing a precision-machined Aluminum 6061 enclosure, you aren't just protecting your hardware from drops—you are protecting your data from the invisible noise of the modern world.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish