Every successful hardware startup eventually hits a wall.

In traditional shops, scaling usually results in a "Quality Tax"—as volume goes up, the attention to detail goes down.

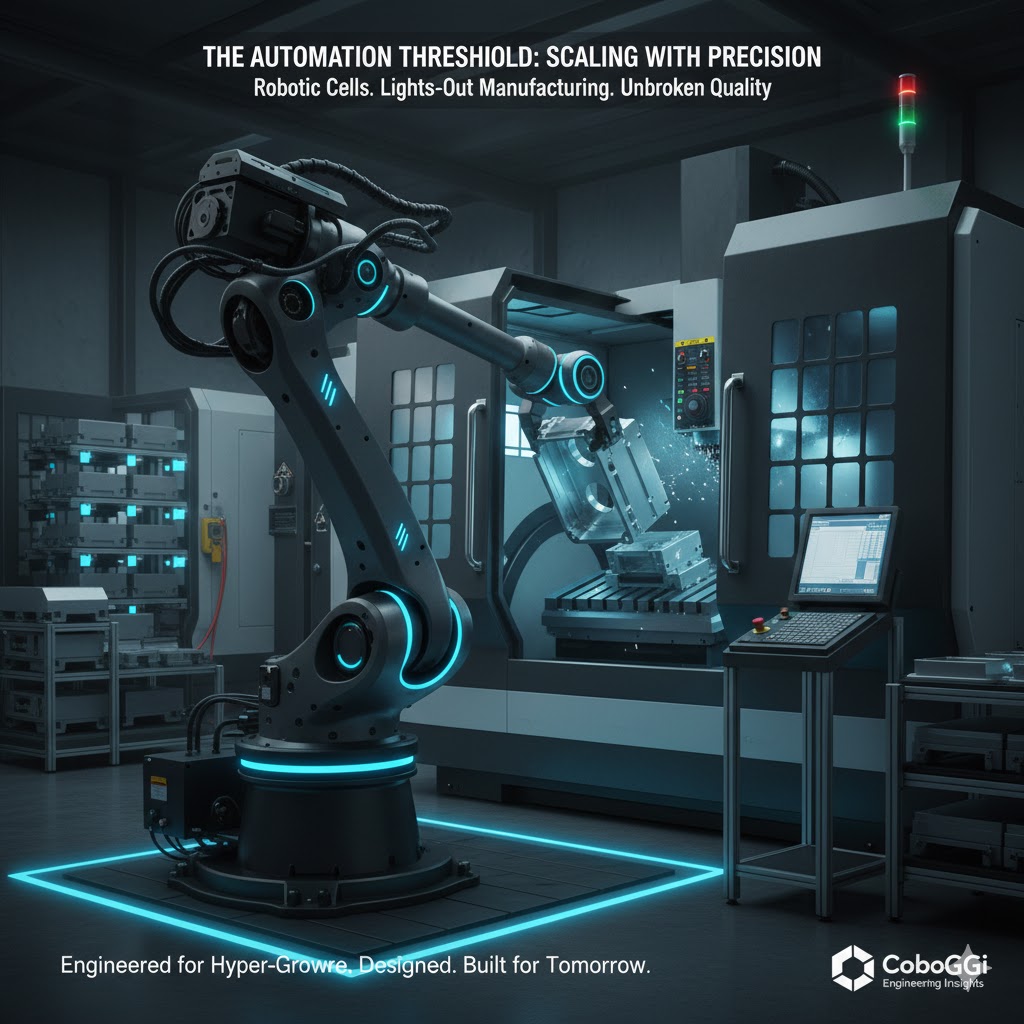

At Coboggi, we bypass this through The Automation Threshold: a data-driven transition to robotic integration that ensures unit #50,000 is identical to unit #1.

1. What is the "Automation Threshold"?

It is the mathematical point where manual labor becomes a liability rather than an asset.

The Manual Era: Great for prototyping, but prone to human fatigue and "shift-change" variance.

The Robotic Era: Coboggi utilizes Robotic Arm Tending for our CNC machines. Robots don't get tired, and they don't have "bad days."

The ROI: By automating the loading and unloading process, we increase "Spindle Up-Time" by up to 40%, allowing us to meet aggressive deadlines without rushing the machining process.

2. Lights-Out Manufacturing: The 24/7 Advantage

"Lights-out" manufacturing refers to production that continues even when the factory lights are off and the staff has gone home.

The Tech: Our advanced CNC cells are equipped with automated pallet changers and tool-breakage sensors. If a tool wears down, the machine detects it, swaps in a fresh tool, and keeps running.

The Business Logic: This maximizes the return on expensive machinery, allowing us to offer more competitive pricing for high-volume orders without cutting corners on material or finish.

3. Maintaining the "Coboggi Standard" at Scale

The biggest fear for a premium brand is that mass production will look "cheap."

In-Process Probing: Our automated lines use infrared probes to measure parts during the cycle. If a dimension drifts by even 5 microns, the system auto-corrects.

Consistency: Automation ensures that the Haptic Density (#46) and the Diamond-Cut Bevels (#49) remain razor-sharp across every single unit.

The Result: You can scale your marketing and sales globally, knowing that your supply chain is an unbreakable engine of consistency.

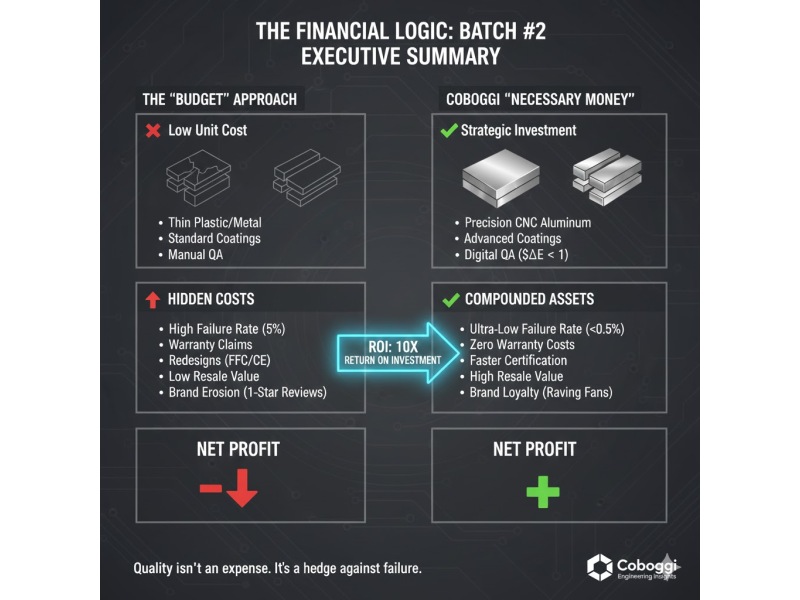

4. Reducing the "Cost per Unit" (CPU)

Scaling isn't just about making more; it's about making them more efficiently.

Labor Efficiency: Automation reduces the "human touch points" per part, which drastically lowers the cost of production at high volumes.

Quality Control ROI: Because robots are highly repeatable, "Scrap Rates" drop significantly. You stop paying for wasted material and start paying for finished, shippable goods.

Conclusion: Ready for the Big Leagues

Scaling is where many hardware brands fail. They choose partners who can't bridge the gap between "Craftsmanship" and "Volume."

At Coboggi, we've integrated both. We provide the soul of a master machinist with the power of a robotic workforce.

We don’t just help you grow; we ensure you grow with your reputation intact.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish