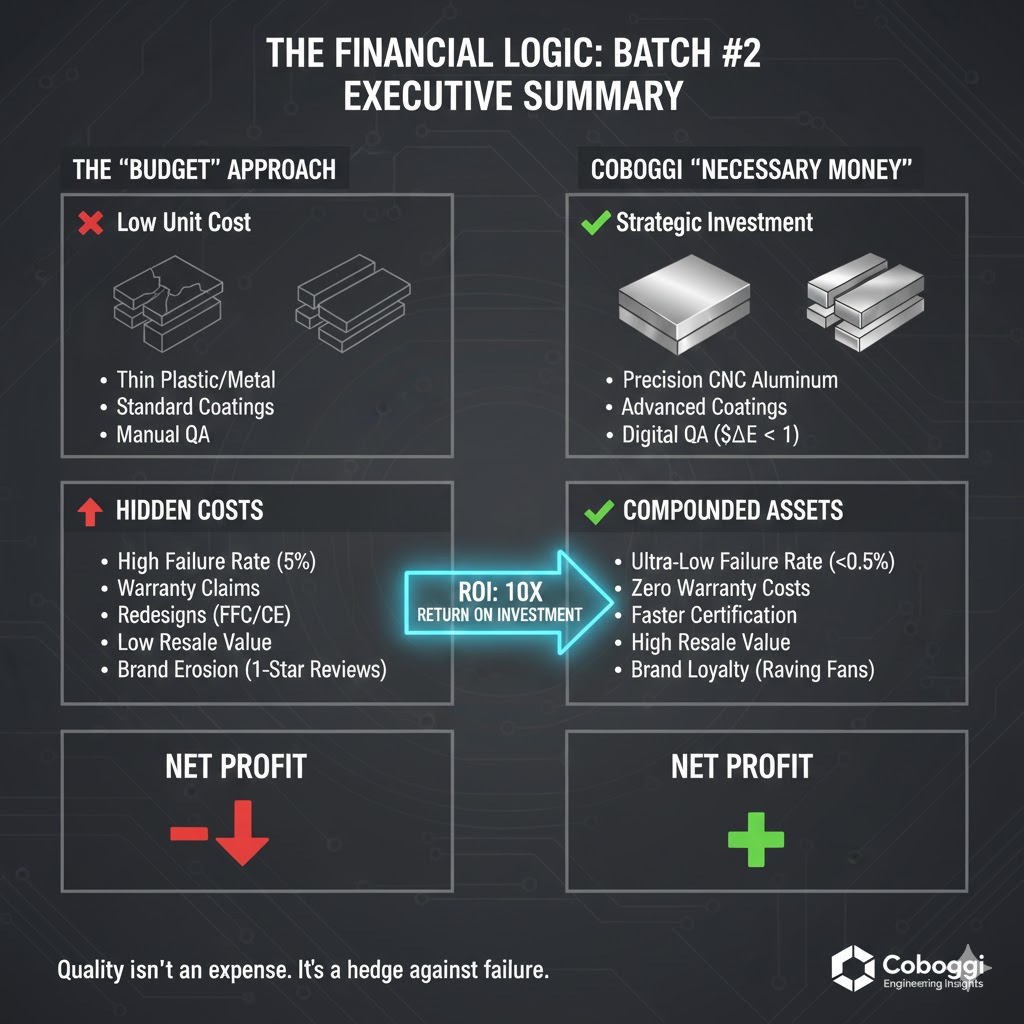

In manufacturing, there is a dangerous trap: The Unit-Cost Fallacy.

This is the belief that saving $2.00 on a chassis or $0.50 on a coating is a "win" for the bottom line. However, in the premium hardware sector, those "savings" often act as a tax on your future profits.

Our previous 10 articles has explored the "Necessary Money"—the strategic investments in aluminum engineering that protect your brand from the hidden costs of failure, returns, and irrelevance.

1. The Financial Guardrails: A Review

We have covered the invisible forces that dictate whether a product succeeds in the market or dies on the shelf:

Chemical Resilience (#42): Avoiding the "corrosion crisis" that triggers mass recalls.

Thermal Reliability (#43): Protecting the internal electronics (the "brains") to extend the product’s lifespan.

Color Consistency (#44): Ensuring global uniformity so your brand looks professional in every market.

Durability vs. Obsolescence (#45): Tapping into the "Buy It For Life" movement to command higher margins.

Haptic Density (#46): Using weight and balance to trigger the "Luxury Response" in the customer's brain.

EMI/RFI Shielding (#47): Using the metal to bypass expensive regulatory hurdles.

Fastener Integrity (#48): Making a product that doesn't feel like "junk" after its first repair.

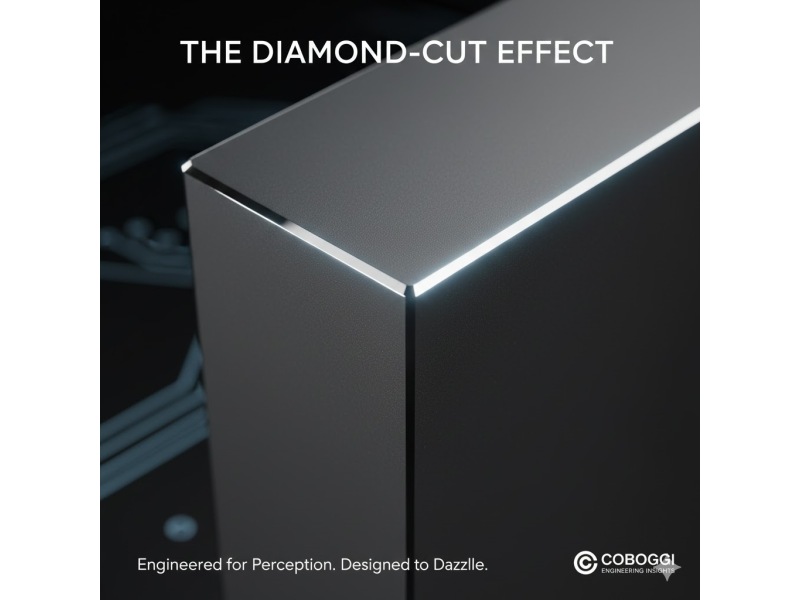

Bevel Physics (#49): Balancing safety with the "Diamond-Cut" aesthetics of precision.

2. The Profitability Shift: From "Cost" to "Asset"

When you work with Coboggi, you stop viewing your aluminum enclosure as a "box" and start viewing it as a Functional Asset.

| The "Budget" Approach | The Coboggi "Necessary Money" Approach | Financial Impact |

| Thin Walls/Plastic | Precision-Milled Aluminum | Lower return rates; higher resale value. |

| Standard Anodizing | Chemical-Resistant/Hardcoat | 3x product lifespan; fewer warranty claims. |

| Loose Tolerances | Micron-Level Precision | Faster assembly; no "rattle" or gaps. |

| External Shielding | Native EMI/RFI Shielding | Thousands saved in FCC/CE certifications. |

3. The Valuation Factor

For a company founder or shareholder, the goal is often Brand Valuation. A brand that is known for "flawless hardware" (like Apple or Leica) trades at a much higher multiple than a brand known for "disposable electronics."

The money you spend on the engineering is an investment in your company's Equity Value. It creates a moat of quality that competitors using "Budget" methods simply cannot cross.

Conclusion: Engineering the Bottom Line

At Coboggi, we don't just build parts; we build Sustainable Business Models. By focusing on "Necessary Money," you eliminate the "hidden taxes" of poor quality and replace them with the "compounding interest" of customer loyalty.

Quality is not an expense—it is a hedge against failure.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish