In premium industrial design, there is a concept called "Monolithic Beauty."

It is the illusion that a complex electronic device—made of dozens of internal parts—has been carved from one single, solid block of metal.

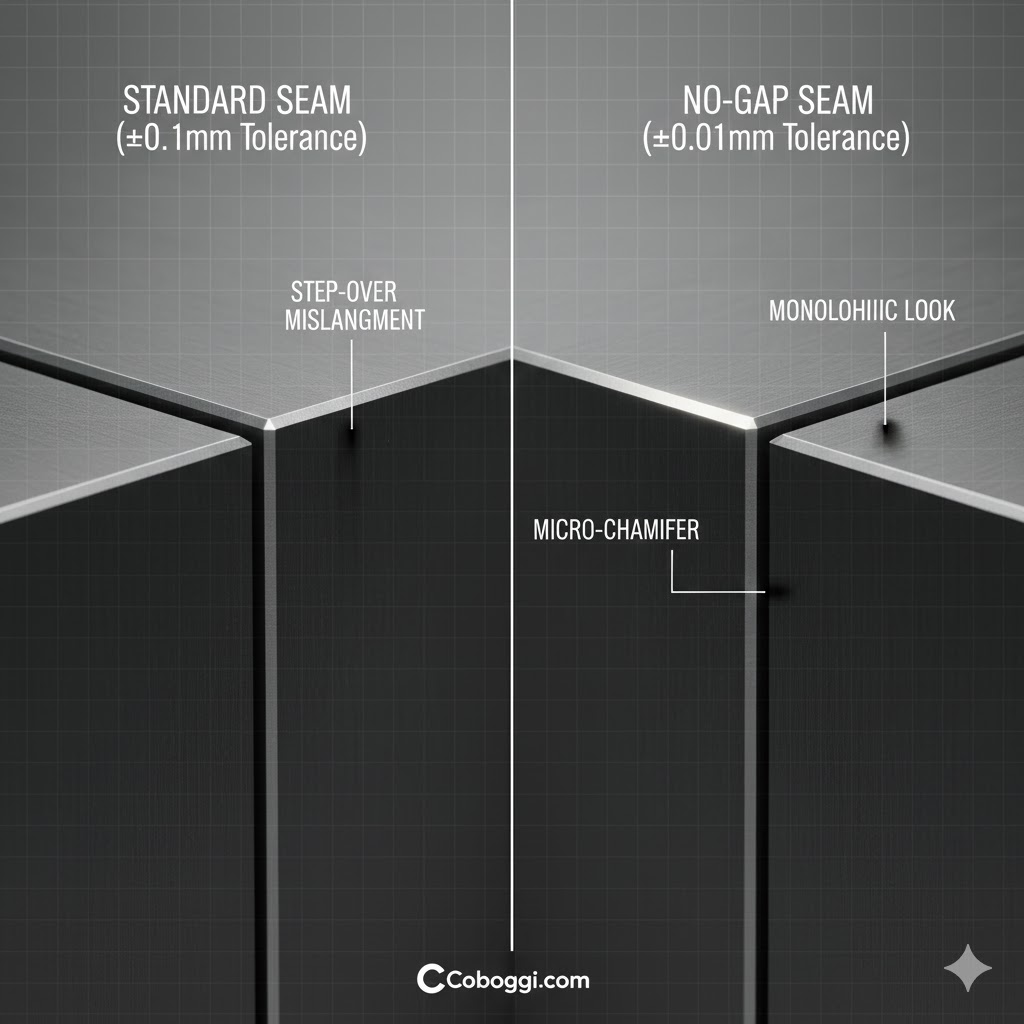

Achieving this "No-Gap" look is one of the hardest challenges in manufacturing. When two pieces of aluminum meet, even a hair-width misalignment can catch the light, creating a "shadow line" that makes the device feel cheap. At Coboggi, we turn invisible seams into a repeatable standard.

1. The Science of the "Hairline" Joint

To the human eye, a gap becomes visible at roughly 0.05mm. To make a seam "disappear," the tolerance of the mating parts must be significantly tighter than that.

The Coboggi Standard: We machine mating surfaces to ±0.01mm.

Why it works: By ensuring that the "Male" and "Female" edges of an enclosure are perfectly parallel and flat, the two parts compress together so tightly that light cannot enter the crack, eliminating the shadow that reveals a seam.

2. Managing "Step-Over" Misalignment

A seam isn't just about the gap between parts; it’s about the flushness (the height difference) between them. If one part is 0.02mm higher than the other, you will feel a sharp edge when you slide your finger across it.

The Solution: We use integrated machining. We often mount the two halves of an enclosure together during the final finishing pass of the CNC process. This ensures the outer profile is cut as one continuous surface, guaranteeing a perfectly flush transition.

3. The Role of Anodizing in Seam Design

Anodizing adds a layer of aluminum oxide to the surface, which actually increases the dimensions of the part by a few microns.

The Engineering Challenge: If you don't account for the thickness of the anodized layer (5 μm to 20 μm), the parts that fit perfectly as raw metal will no longer close properly after they are colored.

Coboggi's Precision: We calculate the "Anodizing Allowance" into our CAD models, ensuring the "No-Gap" fit is achieved after the final finish is applied.

4. Sharp Edges vs. Micro-Chamfers

True "zero-gap" design often requires a Micro-Chamfer (a tiny $45^\circ$ angle at the edge).

The Optical Illusion: By adding a 0.05mm chamfer to both mating edges, we create a deliberate, microscopic V-shape. This catches the light uniformly, making the transition look like an intentional design element rather than a manufacturing error.

5. Applications: Where "No-Gap" Matters Most

High-End Remote Controls: Where the hand is constantly feeling the edges.

Luxury Laptop Chassis: Where the lid meets the palm rest.

Boutique Audio DACs: Where a solid, "heavy" look is essential for brand identity.

Conclusion: Precision You Can Feel

The "No-Gap" aesthetic is the ultimate expression of manufacturing mastery. It tells the customer that every micron of their device was considered. At Coboggi, we don't just make boxes; we create seamless experiences.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish