The electronics industry is facing a reckoning. As consumers and regulators demand lower carbon footprints, the materials we choose for our devices are under the microscope.

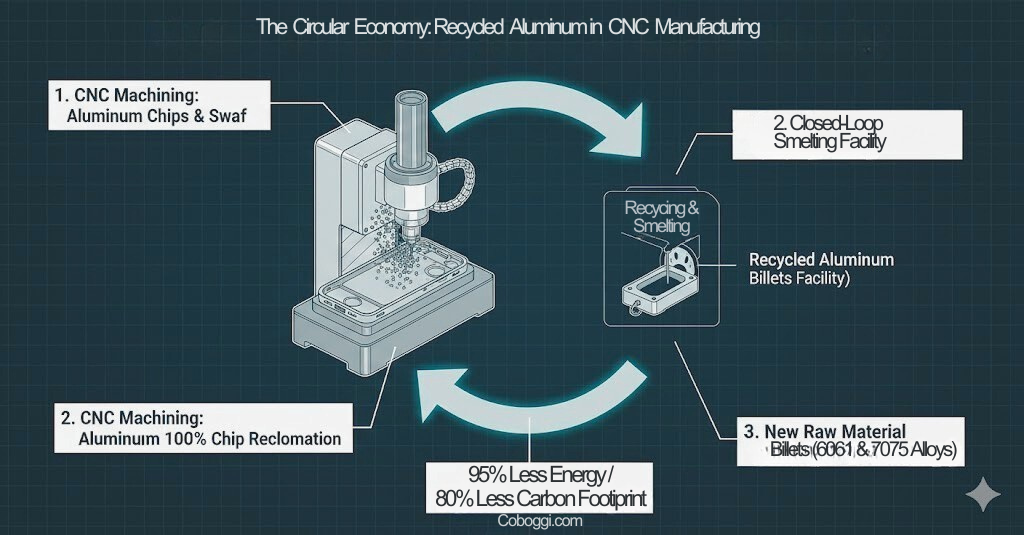

Aluminum has always been "recyclable," but the future of manufacturing lies in Recycled Aluminum and Closed-Loop CNC processes.

At Coboggi, we are helping our clients transition to a circular manufacturing model. Here is how aluminum is leading the charge toward sustainable hardware.

1. The Energy Miracle of Recycled Aluminum

Creating "Primary" (virgin) aluminum from bauxite ore is an incredibly energy-intensive process.

The 95% Rule: Recycling aluminum requires 95% less energy than producing primary aluminum.

Carbon Impact: By switching to recycled 6061 or 7075 alloys, a brand can reduce the "embedded carbon" of its device enclosure by up to 80%.

2. Closed-Loop Machining: Zero Waste CNC

CNC machining is subtractive—we start with a block and remove material. In a standard factory, the "chips" (swarf) left behind are often treated as waste.

The Coboggi Way: We practice closed-loop recycling. 100% of the aluminum chips generated during our CNC process are collected, cleaned of coolants, and sent back to the smelter to be turned into new aluminum billets.

Material Efficiency: This ensures that even if a design requires removing 60% of the material from a block, that "lost" metal is back in the supply chain within weeks.

3. The Quality Myth: Is Recycled Aluminum Weaker?

A common misconception is that recycled aluminum is lower quality.

The Reality: Aluminum is infinitely recyclable. Its atomic structure does not degrade during the melting process.

Technical Purity: As long as the scrap is sorted correctly (keeping 6xxx series separate from 7xxx series), the resulting recycled billet meets the exact same ASTM and ISO standards for strength, conductivity, and anodizing quality as virgin metal.

4. Anodizing and the Environment

Sustainability isn't just about the metal; it's about the chemistry.

Eco-Friendly Finishing: We are moving toward "Heavy-Metal Free" dyes and closed-loop water filtration systems in our anodizing lines. This prevents harmful runoff and reduces the water footprint of every smartphone frame or IoT housing we produce.

5. Why ESG Matters for Your Brand

Investors and retailers are now looking at ESG (Environmental, Social, and Governance) scores.

Consumer Demand: Gen Z and Millennial buyers are actively choosing brands that use "Recycled Materials."

Supply Chain Security: Using recycled aluminum reduces dependence on volatile global mining markets, providing a more stable and ethical supply chain.

Conclusion: Building a Lasting Future

The move toward sustainable CNC machining is the next great frontier in 3C electronics. By choosing recycled alloys and closed-loop manufacturing, you aren't just building a better product—you’re building a better future. Coboggi is proud to be the partner that helps you get there.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish