Introduction

In the world of consumer electronics—whether it’s a rugged smartphone case, a high-end electronic atomizer, or a sleek wearable—the housing does more than just hold components. It is the first interaction the user has with your brand.

Customers today equate the "cool-to-the-touch" feel of aluminum with premium quality. But for product designers and sourcing managers, the challenge lies in how to manufacture that housing. Should you opt for the precision of CNC Machining or the scalability of Die Casting?

At Coboggi, we produce housings for some of the most demanding consumer tech applications. Here is our guide to choosing the right process for your next electronic device.

1. The Aesthetic Battle: The "Premium Feel"

In consumer electronics, appearance is everything. This is where the gap between the two processes is widest.

The CNC Advantage: The "Apple" Standard

If you are aiming for the finish seen on a MacBook or a high-end smartphone frame, CNC machining is usually the only choice.

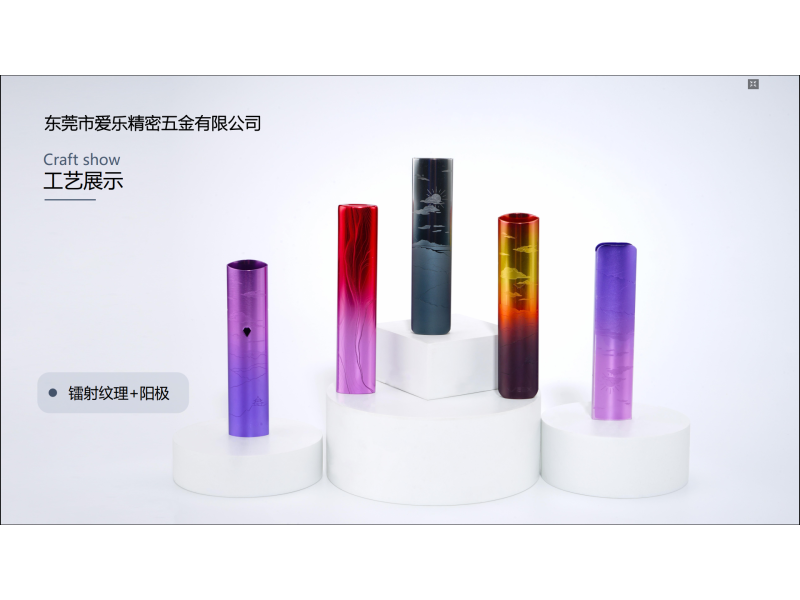

Alloys: CNC allows you to use AL6061 or AL6063. These are high-purity aluminum alloys that accept anodizing perfectly.

Finish: You can achieve vibrant colors, a smooth matte bead-blasted texture, or a high-gloss polished look.

Tactility: CNC parts feel denser and more solid. For an electronic atomizer, where the hand-feel is part of the user experience, CNC provides a luxurious weight and texture.

The Die Casting Reality

Die casting typically uses alloys like ADC12 or A380, which contain high silicon to help the metal flow into the mold.

The Anodizing Problem: Silicon does not anodize well. It creates a dark, splotchy, or uneven grey finish.

Surface Treatment: Die-cast consumer electronics almost always require painting, powder coating, or E-coating to hide the surface imperfections. If you want a raw metallic look, die casting struggles to deliver.

Coboggi Tip: If your design calls for a clear or bright colored metallic finish (Red, Blue, Gold), stick with CNC Machining.

2. Thermal Performance: Managing the Heat

Heat management is critical for devices like electronic atomizers (which generate high heat rapidly) and high-performance smartphones.

CNC Machining: Machined housings are made from a solid billet of extruded aluminum. This material has a uniform grain structure, offering superior thermal conductivity (heat transfer). It pulls heat away from the battery and chipset efficiently, acting as a natural heat sink.

Die Casting: High-speed injection can trap microscopic air bubbles (porosity) inside the metal walls. Air is a poor conductor of heat. While die-cast aluminum is still better than plastic, it is generally less efficient at heat dissipation than CNC aluminum.

3. Precision and Assembly

Consumer electronics are packed tight. PCBs, batteries, and screens fight for every millimeter of space.

Waterproofing (IP Ratings): If your phone case or atomizer needs to be water-resistant (IP67/IP68), the mating surfaces must be perfectly flat to compress O-rings. CNC machining holds tolerances of pm 0.01mm, ensuring a watertight seal every time.

Thin Walls: CNC can machine incredibly thin walls (down to 0.5mm) without warping, allowing you to keep the device slim and lightweight. Die casting often requires slightly thicker walls to ensure the metal flows properly during molding.

4. Time-to-Market: The Speed of Trends

The consumer electronics market moves fast. A delay of two months can mean missing a holiday sales window.

CNC Machining (The Sprinter): We can take your CAD file and have a physical prototype in your hand in 3 to 5 days. If the button placement on your new atomizer is off by 1mm, we just update the code and machine the next batch instantly.

Die Casting (The Marathon Runner): Building the steel tool (mold) takes 4 to 8 weeks. Once the mold is made, changing the design is extremely expensive and slow.

The Hybrid Strategy:

Many of our clients launch their product using CNC Machining to hit the market early. Once the product goes "viral" and demand hits 10,000+ units per month, they invest in a die-casting mold to lower costs for the second batch.

Summary Table: Electronics Edition

| Feature | CNC Machining | Die Casting |

| Ideal For | High-end vapes, premium phone bumpers, prototypes, limited editions. | Budget phone internals, mass-market device housings, heat sinks. |

| Surface Finish | Premium. Perfect for Anodizing (Color/Clear). | Standard. Best for Painting or Powder Coating. |

| Production Volume | Low to Medium (1 - 2,000 units). | High Volume (5,000+ units). |

| Flexibility | High. Great for iterating designs quickly. | Low. Design must be frozen before tooling. |

| Durability | High impact resistance (Drop protection). | Good, but brittle if porosity is present. |

The Verdict: What Should You Build?

Go with CNC Machining if:

You are building a flagship product (High-end atomizer, premium phone case).

Your selling point is the aesthetic, metallic beauty of the device.

You need excellent heat dissipation for performance.

You are in the prototyping or market-testing phase.

Go with Die Casting if:

You are building a budget-friendly or mid-range device.

You expect to sell tens of thousands of units immediately.

The housing will be painted, rubberized, or covered, so the raw metal finish doesn't matter.

The housing is purely structural (internal) and not visible to the user.

Ready to Prototype Your Device?

At Coboggi, we understand the demanding standards of the consumer electronics industry. Whether you need a single prototype to show investors or a production run of 1,000 anodized housings for your product launch, we have the machinery and expertise to deliver.

[Contact Us Today for a Quote]

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish