The Backbone of Quality: Why Tolerances Define Your Product

In the world of Original Equipment Manufacturing (OEM), the casing is rarely just a box. It's the functional, protective, and often aesthetic core of your product—whether it’s a rugged industrial controller, a sleek medical device, or a high-performance consumer electronic. But a beautiful design only translates into a high-quality product when its manufacture adheres to precision machining tolerances.

Simply put, a tolerance is the permissible limit of variation in a part’s dimension. No two manufactured parts are ever identical. The difference between a design that clicks together flawlessly and one that requires forcing, rework, or worse, fails in the field, is defined by how well those tolerances are specified and maintained. For Coboggi, delivering world-class OEM casings means mastering these limits.

The Fundamentals: Unilateral, Bilateral, and Stack-Up

Before diving into the specifics, it's vital to understand the language of tolerance:

Bilateral Tolerance: Variation is allowed both above and below the Nominal Dimension. Example: 10.00 +/- 0.05mm means the dimension can be between 9.95 mm and 10.05 mm .

Unilateral Tolerance: Variation is allowed in only one direction from the nominal. Example:

. This is often preferred for ensuring specific fit types.

. This is often preferred for ensuring specific fit types.Tolerance Stack-Up: This is the most critical issue in casing design. It's the cumulative effect of the individual tolerances of multiple components in an assembly. Tightening one feature might be pointless if its mating feature has a loose tolerance, leading to a large overall assembly gap.

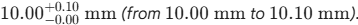

Going Beyond Dimensions: Geometric Dimensioning and Tolerancing (GD&T)

For complex OEM casings, simple linear dimensional tolerances (\pm X.XX mm are often insufficient. They only control the size of a feature, not its true form or location. This is where Geometric Dimensioning and Tolerancing (GD&T) becomes essential.

GD&T is a symbolic language used on engineering drawings to explicitly define the design intent, focusing on how features relate to one another . For an OEM casing, the most critical GD&T controls typically involve:

Position Tolerance: Controls the location of features, like mounting holes, relative to a defined set of Datums. This is paramount for ensuring the PCB, fasteners, and internal brackets align perfectly.

Flatness and Parallelism: Crucial for mating surfaces. If a casing requires a dust or water-tight seal (via a gasket), the flatness of the sealing surface is directly proportional to the product's IP rating. Parallelism ensures one feature is perfectly level with another, which is vital for component alignment.

Perpendicularity: Ensures features are exactly 90° to a datum. For example, a sidewall where a connector is mounted must be perpendicular to the base plate to prevent stress on the connector.

The Cost Curve: The Trade-off of Precision

One of the most common pitfalls in product development is over-specifying tolerances. It's a natural inclination to demand maximum precision, but this comes with a steep price tag.

The cost to machine a feature increases exponentially as the tolerance band narrows. Moving from a standard tolerance of pm 0.1 mm to a high-precision tolerance of pm 0.01 mm could easily double or triple the machining time, increase the required quality checks, and dramatically reduce the number of machine tools capable of achieving the spec.

Coboggi Insight: Only specify tight tolerances on functional features, such as mating surfaces and datum references. Keep non-critical features (like internal pocket depths or outer wall thickness) to standard machining tolerances to manage costs without sacrificing product quality.

Best Practices for Flawless Casing Design

To ensure your OEM casing moves smoothly from design to high-volume manufacturing, follow these three core principles:

Define Robust Datums: A datum is the theoretical, perfect plane, line, or point from which all critical measurements are taken. Choosing stable and easily accessible features as your primary, secondary, and tertiary datums is the foundation of GD&T.

Focus on Function: Before assigning a tolerance, ask: "What does this feature do?" If it mounts a high-precision bearing, the tolerance must be tight (e IT6 or IT7 ). If it's just the aesthetic edge of the casing, a standard milling tolerance is likely sufficient.

Consider Material Properties: The material choice dictates the achievable tolerance. Softer materials are harder to hold tight tolerances on, and materials with high coefficients of thermal expansion (like some plastics or light metals) will have their effective tolerances change significantly with temperature.

Conclusion

At Coboggi, we view the specification of machining tolerances as an engineering art—a critical balance between absolute function, predictable assembly, and cost-effective manufacturing. By meticulously applying the principles of GD&T and understanding the manufacturing capabilities of high-precision CNC equipment, we ensure that every OEM casing we produce is not just a part, but a perfectly engineered solution.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Khmer

Khmer Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish